1. Temperature control

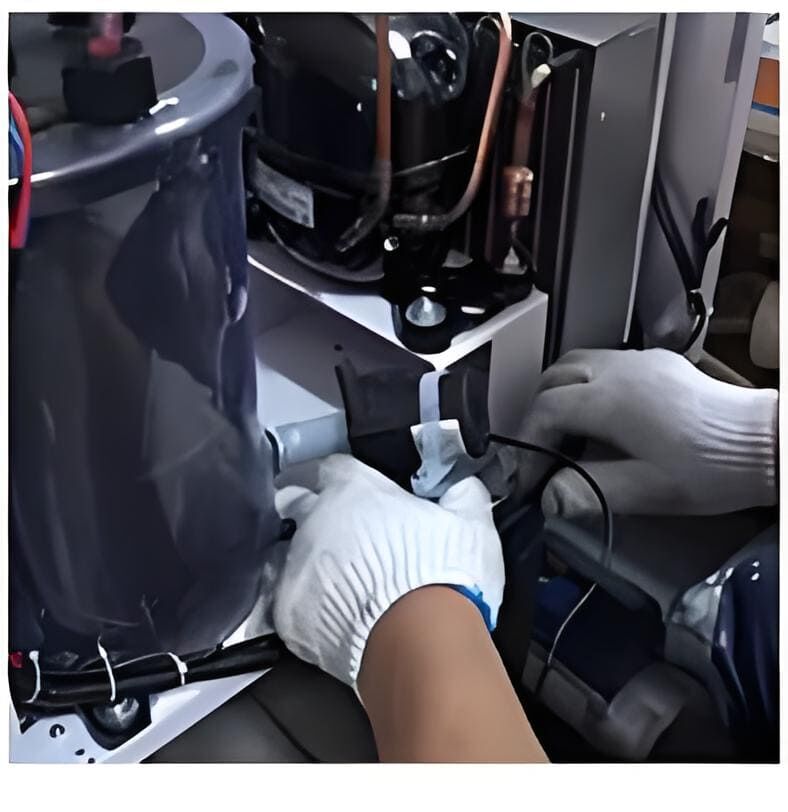

During the operation of the laser engraving machine, the laser will generate a lot of heat. Excessive temperature will affect the performance of the laser and the engraving quality. The chiller keeps the laser and other components within a suitable operating temperature range by circulating cooling water, ensuring the stability of the equipment and the engraving effect.

2. Improve engraving efficiency

Through effective cooling, the laser engraving machine can operate at a higher power, thereby improving the engraving speed and efficiency. The application of the chiller enables the laser engraving machine to maintain its performance under long-term high-intensity work and reduce downtime caused by overheating.

3. Extend equipment life

Proper temperature control can reduce the wear of the laser and other components and reduce the failure rate, thereby extending the service life of the laser engraving machine. The use of the chiller helps to maintain the long-term stability of the equipment and reduce maintenance and replacement costs.

4. Wide range of applications

The chiller is not only suitable for laser engraving machines, but also can be used for other laser equipment that requires temperature control, such as laser cutting machines, laser marking machines, etc., and has a wide range of application prospects.

Copyright © 2025 ZIBO LIZHIYUAN ELECTROMECHANICAL EQUIPMENT CO., LTD. Privacy policy