|

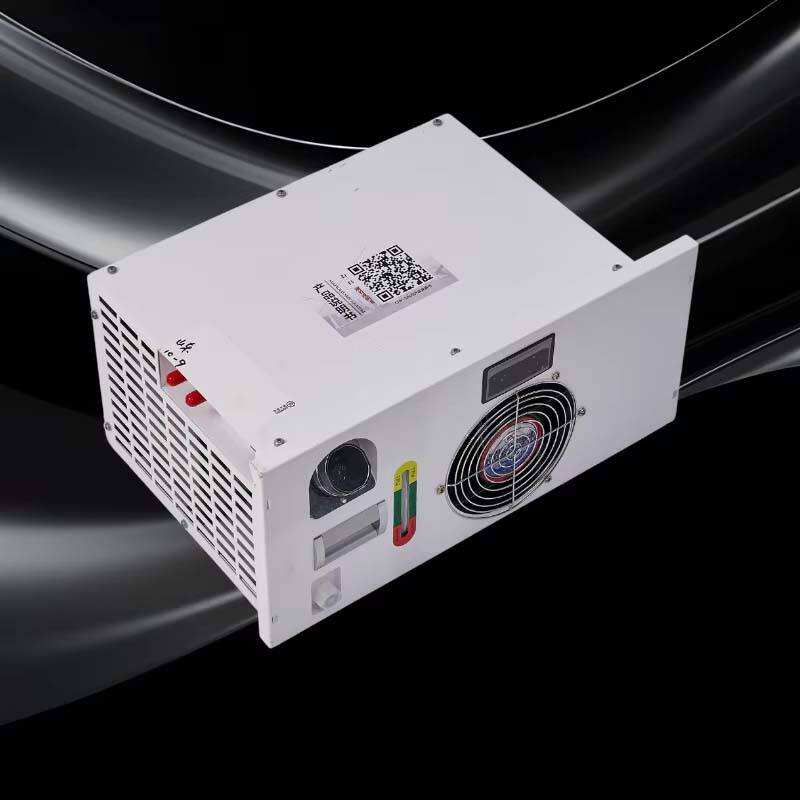

Model

|

CW-3000TG

|

CW-3000DG

|

CW-3000TH

|

CW-3000DH

|

|

AC 1P 220-240V

|

AC 1P 110V

|

AC 1P 220-240V

|

AC 1P 110V

|

|

|

Frequency

|

50/60Hz

|

60HZ

|

50/60Hz

|

60HZ

|

|

0.4-0.7A

|

0.4-0.9A

|

0.3-0.6A

|

0.3-0.8A

|

|

|

Rated power of the whole machine

|

0.07KW

|

0.088KW

|

||

|

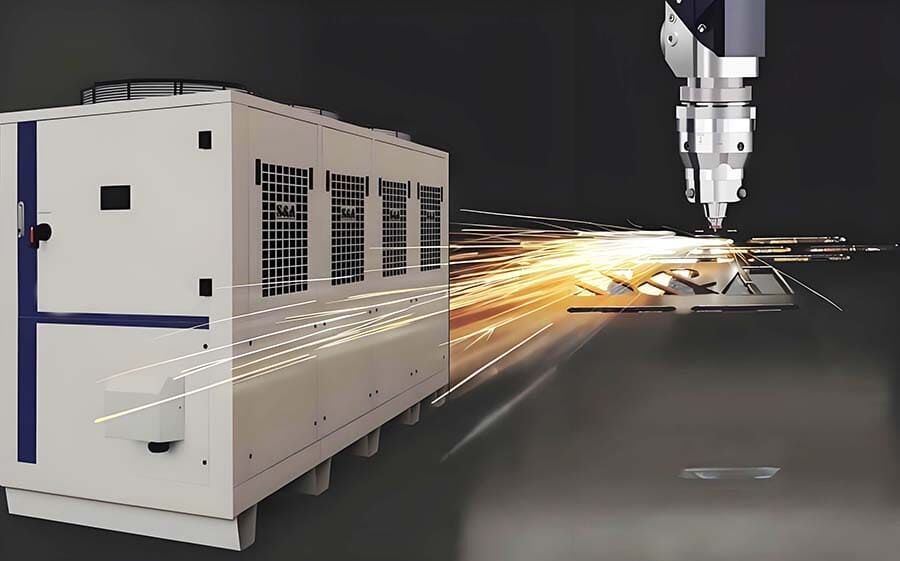

50W/℃

|

||||

|

Maximum head

|

13M

|

25M

|

||

|

13/min

|

27L/min

|

|||

|

Inlet and outlet

|

φ10Copper Tsui Pagoda(default)/φ8Connector/φ10Connector/φ

|

|||

|

9L

|

||||

|

Machine dimensions

|

Length *Width *Height 465*265*400mm(L×W×H)

|

|||

|

Length *Width *Height 550*340*430mm(L×W×H)

|

||||

|

Net weight

|

9Kg

|

10Kg

|

||

|

11Kg

|

12Kg

|

|||

|

Security

|

Flow alarm

|

|||

Copyright © 2025 ZIBO LIZHIYUAN ELECTROMECHANICAL EQUIPMENT CO., LTD. Privacy policy