Understanding the Cooling Capacity of the CW5000 Water Chiller

What Does Cooling Capacity Mean for the CW5000 Water Chiller?

The cooling capacity basically tells us how much heat a chiller can pull out each hour, usually measured either in kilowatts or those old school tons of refrigeration units. Take the CW5000 water chiller for instance. The right cooling capacity makes all the difference when it comes to keeping things at just the right temperature during industrial operations such as laser systems or injection molding machines. When there's not enough capacity, equipment starts getting too hot which nobody wants. But if the chiller has sufficient power, it handles bigger heat loads without breaking a sweat, so production lines keep running smoothly day after day. Most manufacturers look at this number first because nobody likes downtime caused by overheated machinery.

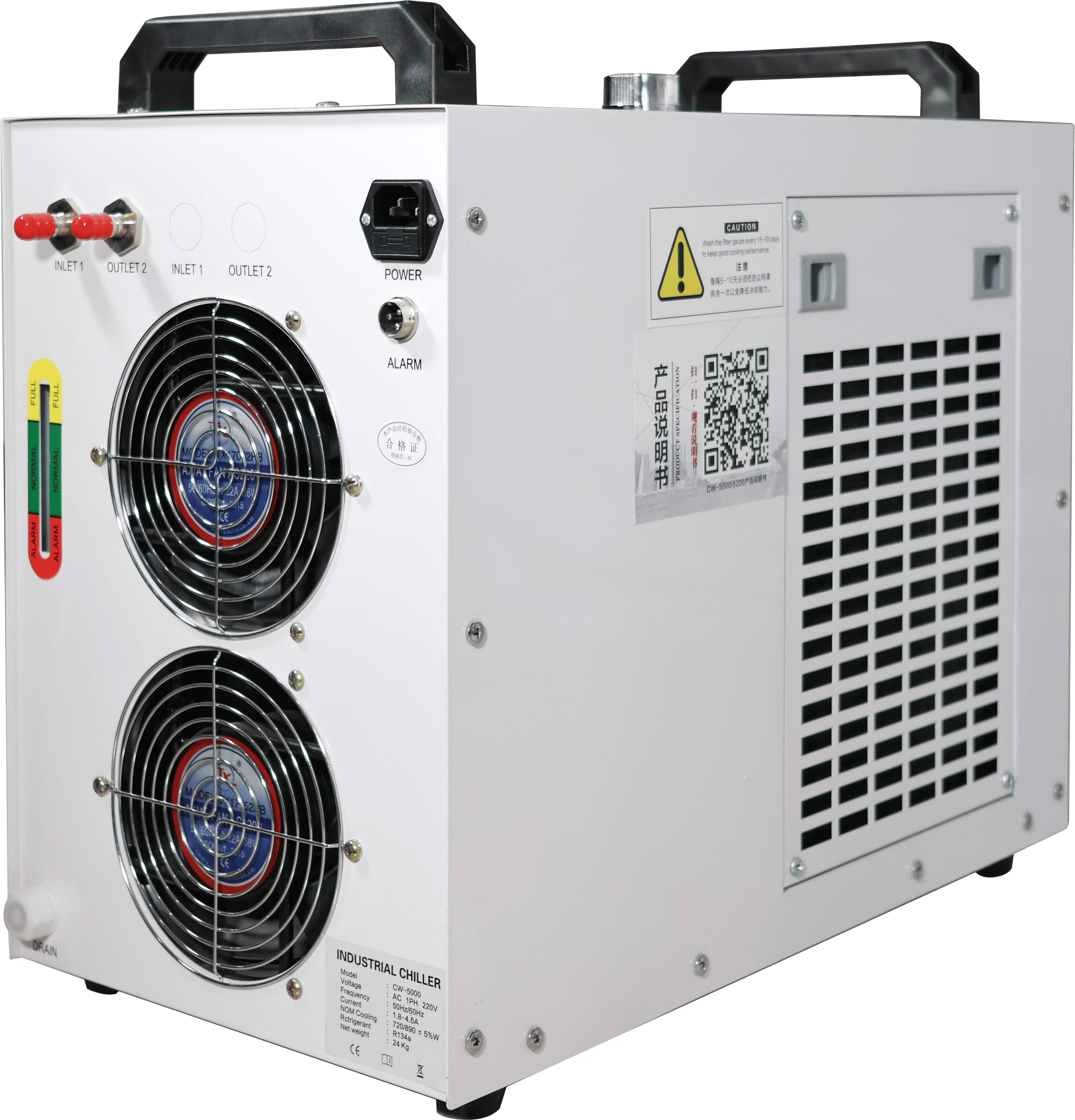

Technical Specifications Defining the CW5000’s Performance

The CW5000 has a cooling capacity rating of 6.5 kW or about 22,200 BTU per hour when operating under normal conditions. Temperature control is pretty accurate too, within plus or minus 0.5 degrees Celsius which matters a lot for delicate operations. What makes this unit stand out is its dual circuit refrigerant design that keeps things running smoothly even during peak usage times. Looking at the specs side by side with something smaller like the CW-3000 that only does 1.2 kW, the bigger model handles heat much better. This makes sense why many shops choose it for their mid power lasers between 50 to 150 watts range as well as those injection molding setups where consistent cooling really counts.

How Ambient Temperature Affects CW5000 Water Chiller Efficiency

When temperatures go above 35 degrees Celsius, the CW5000 tends to lose around 12% of its cooling capacity because the compressor works harder under heat stress. The system does have a variable speed fan though, which changes airflow rates automatically to keep things running as efficiently as possible when it gets warm out. Every time the outside temp goes up by five degrees, expect to see an extra 3 to 5 percent increase in power usage just to maintain normal operation levels. That's why installing these units properly matters so much, especially if they're going into areas where temperature control is already part of the building management strategy.

Role of Refrigerant Type in Maximizing Capacity

The CW5000 model comes equipped with R-513A refrigerant, which serves as a greener option compared to older R-134A variants. What makes this new refrigerant stand out? Well, it actually conducts heat about 15 percent better than its predecessor. This improved thermal conductivity means the evaporator coil works more efficiently, keeping things cool even when the unit runs for extended periods. Getting the refrigerant levels right matters a lot too. If there's just a 10% shortfall in charge, performance drops significantly - around 18% less cooling power basically. And that's not all, the compressor starts working harder and wears out faster. These numbers explain why regular maintenance checks should be part of any service schedule for these systems.

Key Design Features That Optimize the CW5000’s Cooling Performance

Energy-Efficient Compressor Technology in the CW5000 Water Chiller

The CW5000 features a variable-speed scroll compressor that adjusts output based on real-time cooling demands. This reduces energy consumption by up to 25% compared to fixed-speed units while maintaining tight temperature control (±0.5°C). The design also minimizes mechanical stress, contributing to a service life of over 30,000 hours without performance decline.

Advanced Heat Exchange Design for Consistent Output

Equipped with dual-layer stainless steel heat exchangers, the CW5000 achieves 98% thermal transfer efficiency by maximizing surface contact between water and refrigerant. Corrosion-resistant microchannel coils resist scaling in hard water conditions, preserving peak performance in demanding applications such as laser cutting and plastic molding.

Intelligent Temperature Control and Stability

An adaptive PID controller monitors inlet and outlet water temperatures, making over 200 micro-adjustments per minute to stabilize output amid load fluctuations. In high-temperature environments exceeding 40°C, integrated failsafe protocols activate secondary cooling circuits, ensuring uninterrupted operation in critical settings like medical imaging and laboratory equipment cooling.

Real-World Applications and Operational Performance of the CW5000 Water Chiller

Industrial Use Cases of the CW5000 Water Chiller in Laser Cooling

The CW5000 offers solid temperature control for industrial lasers, which helps keep output fluctuations at bay when thermal drift occurs. According to studies published last year, keeping laser temps within just one degree Celsius up or down cuts efficiency losses by around 12 percent over long cutting sessions. For shops running metal fabrication lines or doing detailed engraving work where machines need to run nonstop, this kind of stability is what keeps production on track without constant interruptions for recalibration.

Performance in Plastic Processing and Injection Molding

In injection molding, the CW5000 enables faster cooling rates, improving product dimensional accuracy by 18% compared to standard chillers, according to Plastics Today (2024). Its adaptive flow control sustains consistent mold temperatures despite ambient fluctuations, reducing cycle times by 14% in PET production trials and enhancing overall throughput.

Reliability in Laboratory and Medical Equipment Cooling

For medical imaging systems such as MRI machines, temperature stability below ±0.5°C is essential to prevent image artifacts. The CW5000 maintains this threshold for 98.6% of operational hours in ISO 9001-certified laboratories. Dual refrigeration circuits provide redundancy, ensuring dependable cooling for sensitive applications in pharmaceutical compounding and blood analysis.

Factors That Affect the Actual Cooling Capacity of the CW5000

Water Flow Rate and Its Impact on CW5000 Water Chiller Performance

Optimal water flow rate is crucial for maximizing heat transfer efficiency. Insufficient flow reduces cooling effectiveness, forcing the system to work harder, while excessive flow can stress components and shorten equipment life. Following manufacturer specifications helps avoid a potential 10–15% drop in performance and ensures long-term reliability.

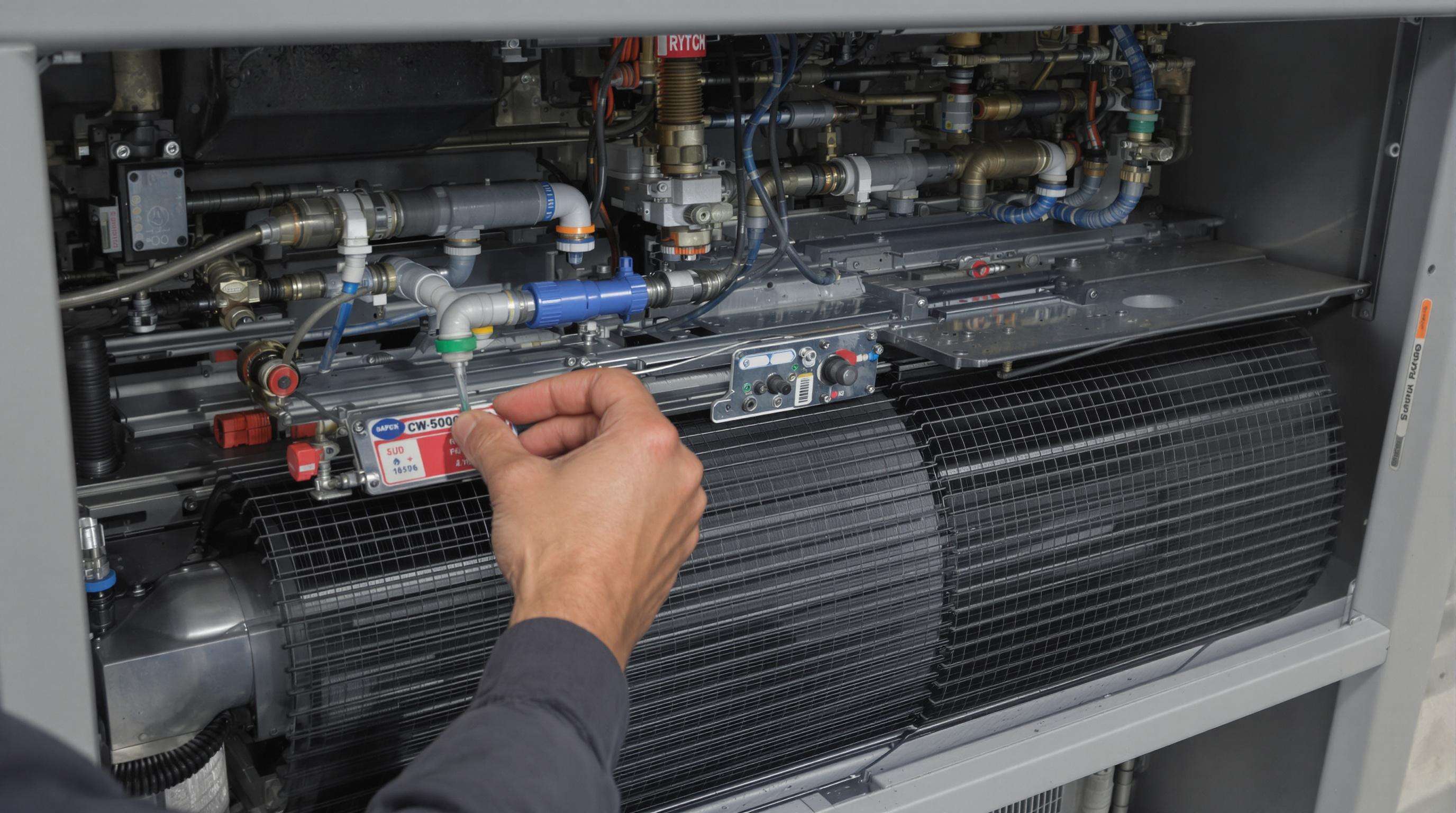

Maintenance Practices to Sustain Optimal Capacity

Keeping up with regular maintenance really helps keep the CW5000 running efficiently and makes it last longer too. When dust builds up on those heat exchanger surfaces, it can actually cut down on how well heat gets dissipated by around 20 percent or so. And if refrigerant levels drop too low, that means the system just isn't going to cool as effectively either, probably somewhere between 12% and 18% less effective. For best results, most technicians recommend cleaning those condenser coils at least once every three months. Air filters should be swapped out roughly every three to six months depending on usage conditions. Checking refrigerant pressure twice a year is also pretty important for maintaining optimal performance over time.

Comparison of Rated vs. Real-World Cooling Output

The CW5000's rated capacity figures come from lab tests done under perfect conditions around 22 degrees Celsius with 50% humidity, but things get different in actual facilities. When temperatures fluctuate throughout the day or there are periods of heavy usage, the cooling effectiveness drops somewhere between 15 and 20 percent. For those working with sensitive equipment like lasers where even small changes matter, it's really important to factor in these real world variations when planning out how to manage heat. Otherwise, what works great in controlled environments might fall short when put to the test in everyday operations.

FAQ

What is the cooling capacity of the CW5000 water chiller?

The CW5000 water chiller has a cooling capacity rating of 6.5 kW or about 22,200 BTU per hour under normal operating conditions.

How does ambient temperature affect the CW5000's performance?

When ambient temperatures exceed 35 degrees Celsius, the CW5000 loses approximately 12% of its cooling capacity. The unit also increases power usage by 3 to 5 percent for every 5-degree increase in temperature.

What refrigerant does the CW5000 use?

The CW5000 uses R-513A refrigerant, which is more environmentally friendly and has improved thermal conductivity compared to older R-134A variants.

How important is regular maintenance for the CW5000?

Regular maintenance is crucial to ensure optimal performance. It includes cleaning the heat exchanger surfaces, replacing air filters, and checking refrigerant pressure to avoid performance drops.