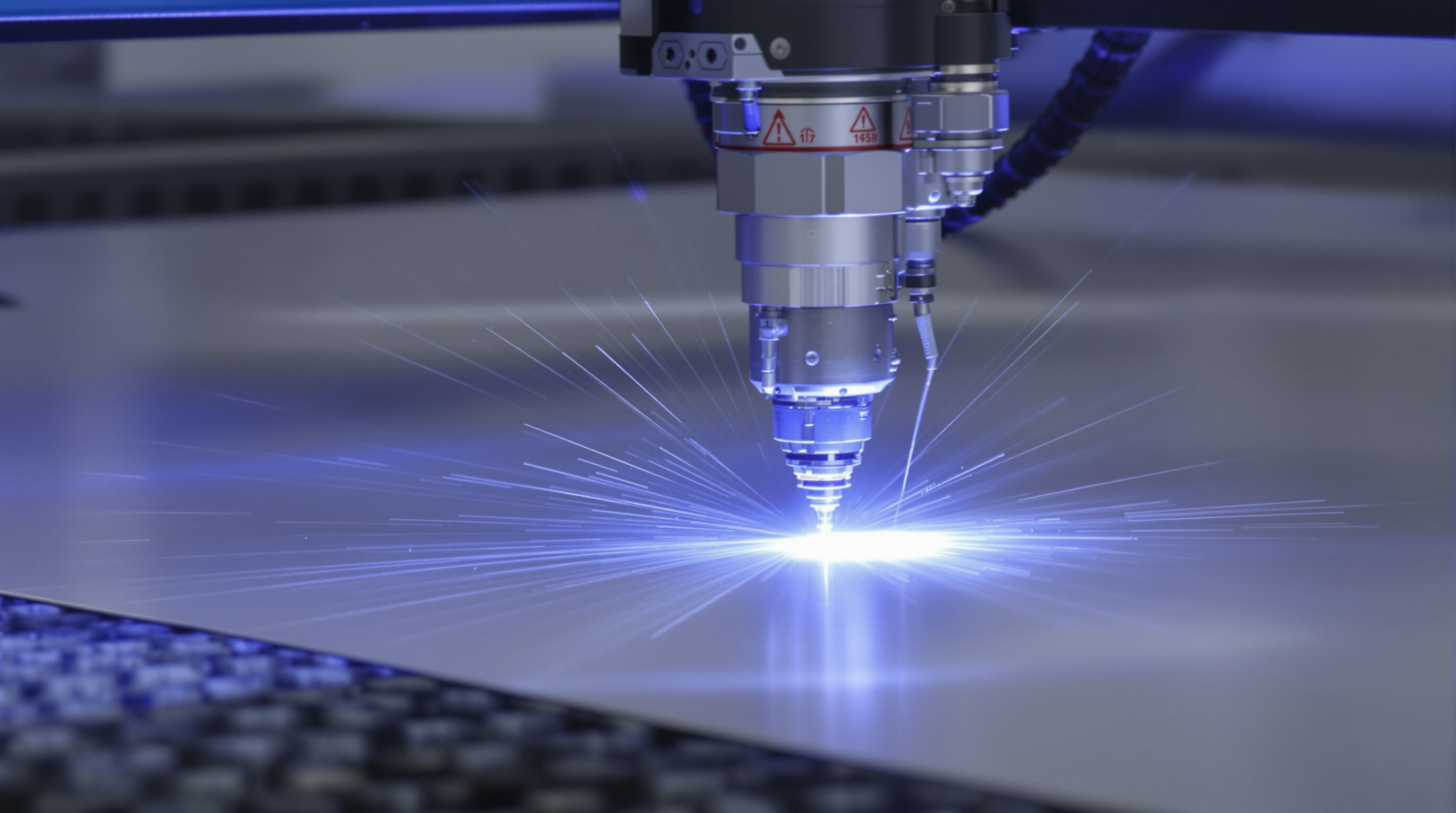

The Critical Role of Temperature Stability in CO2 Laser Chillers Performance

Understanding the Optimal Operating Temperature Range for Laser Cutting Machines

CO2 lasers work best when kept within a pretty tight temperature range, around 15 to 25 degrees Celsius according to some recent research from MonPort Laser in 2023. Maintaining this sweet spot helps keep the molecules stable in the gas mix inside the laser while also letting heat escape properly. And this matters because most of what goes in doesn't actually turn into useful light output – we're talking about roughly 10 to 20 percent efficiency at best. When temps go over 25°C, things start getting messy at the molecular level. The emission spectrum gets wider and the beam loses its sharpness. On the flip side, if it drops below 15°C, the cooling fluid becomes thicker and harder to move through the system, which slows down how quickly everything responds to changes.

How Thermal Effects on CO2 Laser Output and Stability Impact Performance

Changes in temperature really mess with beam quality because they cause wavelength drift at around 0.03 nm per degree Celsius and also deform the discharge tubes as noted in PolyScience research from 2023. When temperatures go up just one degree Celsius, output power drops between half a percent and full percent due to those upper energy states getting depleted. Things get even worse when there are three degree variations which can actually move focal points by as much as 50 microns in standard 100 watt systems. Looking at maintenance records across industries shows these temperature related problems account for nearly four out of five instances where lasers stop working properly, making good thermal management absolutely essential for keeping operations running smoothly.

The Importance of Temperature Stability in Laser Performance

Keeping temperature stable within plus or minus half a degree Celsius helps keep power fluctuations below about 2 percent, maintains consistent focal lengths around 10 microns, and can actually make tubes last roughly 3,000 extra hours before needing replacement. The advanced cooling systems achieve these tight controls through PID regulated heat exchangers that adjust themselves based on what's happening in the surrounding environment and how much load they're handling. This becomes really important when dealing with those higher power systems above 1 kilowatt because the way heat builds up over time makes things far more unstable if not properly managed from the start.

How Laser Chillers Achieve and Maintain Optimal Operating Temperatures

The Science Behind Heat Exchange in Laser Cooling Systems

Laser chillers work by circulating water or water mixed with glycol through a closed loop system that pulls heat away from sensitive optical parts and the laser resonator itself. Once the coolant gets hot, it goes back into the chiller unit where a refrigeration process kicks in, moving all that excess heat out into the surrounding air through what's basically a fancy heat exchanger powered by a compressor. For industrial applications, these systems can keep temperatures stable within about half a degree Celsius thanks to smart algorithms working alongside continuous flow checks according to research published last year in Laser Thermal Management Reports. This kind of precision makes sure everything runs smoothly even when there are changes in workload throughout the day.

Role of Newton’s Law of Cooling in Laser Thermal Management

According to Newton's law of cooling, how fast heat moves around depends largely on how much hotter something is than the surrounding air. Modern chillers actually work with this basic idea, changing fan speeds and adjusting refrigerant pressure as needed. Some research from last year showed these kinds of smart cooling systems cut down power surges by about 19 percent when compared to older fixed-speed models. This not only makes them run better but also helps keep things stable during operation, which matters quite a bit in industrial settings where consistency counts.

Water-Cooled vs. Air-Cooled Heat Dissipation Methods

Air cooled chillers work by using fans along with radiator systems, which makes them good choices when space is limited or installations need to be kept small. Water cooled alternatives actually perform much better when it comes to maintaining stable temperatures during high power operations, around 32 percent improvement over air cooled models when dealing with power levels of four kilowatts or more. These water based systems keep coolant flowing between eighteen to twenty five degrees Celsius, something that helps protect against damage to tubes. Air cooled versions tend to have trouble operating effectively once ambient temperatures go above thirty five degrees Celsius though. Some newer designs now mix both approaches together. Water loops handle the most sensitive parts like optical components while regular air cooling takes care of everything else not so critical. This combination seems to give manufacturers a way to get the best of both worlds without sacrificing too much in terms of either efficiency or dependability.

Impact of Temperature Fluctuations on Beam Quality and Cutting Precision

Impact of Temperature Fluctuations on Beam Quality and Focus Accuracy

For CO2 lasers to work properly, they need pretty strict temperature control around ±0.5°C just to keep that laser beam stable. When temperatures drift outside this range, it messes with the Gaussian intensity pattern, which can cut down on focus accuracy somewhere between 10-12% according to research published in the International Journal of Advanced Manufacturing Technology. If temps swing over 2°C, there's another problem too: kerf width starts varying anywhere from 18% to 25%. That kind of inconsistency really affects how much usable material comes out at the end. Modern day chillers with closed loop cooling systems help fight off these issues though. These advanced setups maintain the necessary precision levels even when running long cuts or dealing with constantly changing conditions on the shop floor.

Coolant Temperature Impact on Laser Power

For every degree Celsius increase in coolant temp, CO2 lasers typically lose between half a percent and one percent of their output power because the gas discharge gets thrown off balance. When running at full capacity for extended periods, this kind of temperature drift adds up fast. After just six hours straight operation without correction, systems can see losses creeping up to 8 or even 10 percent. The good news is that shops investing in better chillers equipped with smart PID controls are seeing remarkable results. These advanced cooling systems keep temps stable within a tight 0.3 degree range around target settings, resulting in consistent performance levels around 99.2% across shifts.

Case Study: Power Drift Due to Inadequate Chiller Control

An automotive parts manufacturer observed 7.8% thickness variation in 3mm aluminum cuts across batches. Investigation revealed a 1.2°C coolant temperature drift from an aging chiller, causing corresponding power fluctuations. After upgrading to a dual-stage chiller with real-time thermal compensation, cutting tolerance improved to ±0.07mm, reducing material waste by $18,000 per month.

Controversy Analysis: Is Sub-Degree Precision Necessary for All CO₂ Laser Applications?

While medical device manufacturing demands ±0.1°C control for micron-level accuracy, 23% of industrial users find ±1°C sufficient for sheet metal cutting. However, research shows even less demanding applications benefit from tighter control—each 0.5°C improvement in thermal stability reduces lens contamination rates by 14% due to more consistent beam characteristics.

Risks of Overheating and Overcooling in CO2 Laser Systems

Laser chillers maintain the 15–25°C range essential for CO2 laser efficiency. Operating outside this window introduces significant failure risks:

Risks of Overheating in Laser Cutting Systems, Including Tube Degradation

Operating above 25°C accelerates thermal stress in the laser tube, decreasing power output by 0.5–1% per 1°C rise. Prolonged overheating weakens glass-to-metal seals in resonator chambers, shortening tube lifespan by 40–60% compared to properly cooled systems.

Dangers of Overcooling, Including Condensation and System Damage

Coolant below 15°C promotes condensation, leading to mirror corrosion within 200 operating hours in humid conditions. Sub-10°C temperatures risk thermal shock during startup, with winter audits showing 18% of overcooled systems develop cracked ceramic insulators.

Seasonal Adjustments for Coolant Temperature (Summer vs. Winter Settings)

| Season | Temperature Strategy | Safety Buffer | Key Benefit |

|---|---|---|---|

| Summer | 19-22°C (compensate ambient) | 3-5°C below | Prevents heat accumulation |

| Winter | 17-20°C (anti-condensation) | 3-5°C above | Avoids thermal contraction |

These seasonal strategies maintain beam focus and component integrity despite ambient shifts, reinforcing why consistent temperature control is fundamental to reliable CO2 laser operation.

Frequently Asked Questions

What is the optimal temperature range for CO2 lasers?

The optimal operating temperature range for CO2 lasers is between 15 and 25 degrees Celsius. Staying within this range ensures molecular stability in the gas mix, proper heat dissipation, and optimal performance.

How does temperature affect CO2 laser performance?

Temperature fluctuations impact CO2 laser performance by causing wavelength drift, deformations in discharge tubes, and shifts in focal points, which can lead to reduced beam quality and cutting precision.

What are the risks of overheating in CO2 laser systems?

Overheating can cause thermal stress in laser tubes, decrease power output, and weaken glass-to-metal seals, reducing tube lifespan by up to 60%.

What are the advantages of water-cooled chillers over air-cooled chillers?

Water-cooled chillers maintain more stable temperatures during high-power operations, resulting in better performance compared to air-cooled chillers, especially when dealing with power levels of 4 kilowatts or more.

Table of Contents

- The Critical Role of Temperature Stability in CO2 Laser Chillers Performance

- How Laser Chillers Achieve and Maintain Optimal Operating Temperatures

- Impact of Temperature Fluctuations on Beam Quality and Cutting Precision

- Risks of Overheating and Overcooling in CO2 Laser Systems

- Frequently Asked Questions