Understanding CO2 Laser Chiller Systems and Cooling Fundamentals

What Is a CO2 Laser Chiller and Why Cooling Matters

CO2 laser chillers serve as specialized cooling units that keep these lasers running at their best temperatures. They work by pumping cooled liquid through the laser tube and other important parts where heat builds up. Most CO2 lasers actually turn around 70 percent of their power into waste heat, so getting rid of this heat properly is really important. Without good cooling, the laser beam can become unstable, performance drops off, and those expensive optical components might get damaged over time. When thermal management works well, it means better results when cutting or engraving materials. Equipment tends to last about half again as long with proper cooling too. Plus there's the safety aspect since overheating can lead to unexpected failures during operation.

Core Principles of Heat Dissipation in Laser Operation

The way heat moves out of CO2 laser systems is pretty straightforward physics at work really. Thermal energy gets moved away from hot parts into something cooler, usually water or air. Chillers do this job using what's called a closed loop system. The compressor pushes refrigerant around, picking up heat from the laser coolant first, then dumping that heat outside through either air or water cooling. Keeping coolant temps right around ±1°C of where they should be is absolutely essential for these machines to run properly. Manufacturers know this well because even small temperature swings of 2-3 degrees can throw off the laser wavelength enough to make cuts less accurate, sometimes dropping precision by nearly 15%. That kind of variation just isn't acceptable in most industrial applications.

Overview of Air-Cooled vs. Water-Cooled CO2 Laser Chillers

Most CO2 laser chillers work with either air cooling or water cooling methods. The air cooled version blows hot air out through fans and those metal fins we see on the sides, which makes them pretty straightforward to install. They're great for small shops or places where getting water isn't easy. Water cooled systems send the heat away through a separate water circuit that connects to something like a cooling tower outside. These tend to handle heat much better and keep temperatures stable when things get busy. Sure, air cooled units cost less initially and don't need as much maintenance, but water cooled ones generally run about 30 to maybe even 50 percent more efficiently. That's why they're often found in factories running non stop where consistent cooling matters most.

Air-Cooled CO2 Laser Chillers: Design, Performance, and Ideal Use Cases

How Air-Cooled Chillers Work in Laser Applications

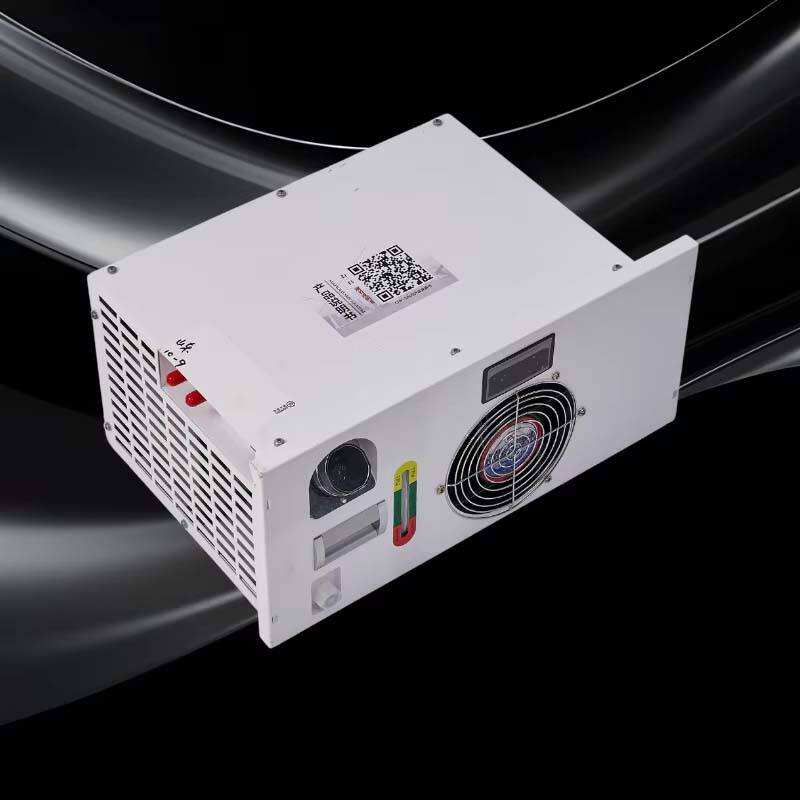

Air cooled CO2 laser chillers work by pulling heat away from the laser system through a refrigerant cycle and then blowing that heat out into the surrounding air with fans and those big condenser coils we always see on top. These chillers are basically all in one boxes so they don't need any outside water connections which makes them really good choice for places where there's no easy access to water or when local regulations limit water usage. When the laser starts running and generating heat, the refrigerant inside takes care of moving that heat to the condenser section. Then the fans kick in and force air across those coils to actually get rid of the thermal energy, closing off the whole cooling process nicely.

Cooling Efficiency and Temperature Stability

Most air cooled chillers keep things pretty stable around plus or minus 1 to 2 degrees Celsius when everything's running normally, though they start having trouble once outside temps hit above 35 degrees. When it gets really hot out there, these units run about 15 to 20 percent slower compared to their water cooled counterparts, which makes them less reliable for jobs needing super tight temperature control. They work just fine in places with average weather patterns and aren't used all day every day, especially where heat demands don't fluctuate too much throughout operation.

Noise Levels, Climate Sensitivity, and Installation Simplicity

The noise level from these systems typically ranges between about 65 to 75 decibels which is similar to what people experience during regular conversations around them. Fan operations are mainly responsible for this sound output. These units tend to be sensitive when it comes to climate conditions. Their performance drops off noticeably when temperatures rise or humidity increases because the condenser coils get dirty more quickly under such circumstances. On the plus side though, installing them isn't complicated at all. All that's needed is access to electricity and proper air circulation space. There's no need to deal with complex plumbing arrangements or any sort of water treatment setup which makes things much simpler compared to other options available on market today.

Best Applications: When Air-Cooled Systems Offer the Best Value

Air cooled CO2 laser chillers work great for smaller shops, schools, and companies that want something simple and affordable. These units handle stop start operation pretty well, which makes sense for places where water isn't readily available or when money is tight. The machines themselves take up little space and don't need much looking after, so they fit right into operations located in areas where the temperature stays fairly consistent throughout the year without getting too extreme either way.

Water-Cooled CO2 Laser Chillers: Precision, Power, and Industrial Scalability

How Water-Cooled Systems Deliver Superior Thermal Regulation

Water cooled CO2 laser chillers work so well because water has this amazing ability to absorb heat. Water can hold about four times more heat than air does, which makes these systems really good at moving heat away from sensitive parts. Most industrial models keep temperatures stable within half a degree Celsius, something that's pretty impressive when running continuously for hours on end. When the coolant stays at just the right temperature, the laser tube doesn't experience those annoying temperature shifts that mess with performance. This stability means better cuts overall, fewer problems with the optics getting damaged, and generally speaking, everything lasts longer before needing replacement. For shops that run multiple lasers day after day, this kind of reliability translates into real money savings over time.

Precision and Long-Term Stability in High-Demand Environments

Water cooled chillers keep things running smooth in factories that need constant operation around the clock. These systems can hold temperatures steady within just half a degree Celsius even when outside conditions change throughout the day. The stability they provide makes all the difference for processes needing extreme precision at the micron level. Factories report seeing less wasted materials and consistently better quality products across production batches. Industry reports suggest water cooling gives about 30 to 40 percent better temperature control compared to standard air cooled systems during peak demand periods. What this means in practice is fewer breakdowns and unexpected shutdowns that disrupt production schedules, something plant managers definitely appreciate during busy seasons.

System Complexity, Footprint, and Operational Requirements

Water cooled chillers need quite a bit more setup than their air cooled counterparts. We're talking actual plumbing connections here folks not just electricity. Most installations will need access to either a municipal water source, some kind of cooling tower arrangement, or at minimum a decent sized closed loop system somewhere nearby. And let's face it space is always an issue too. These systems come packed with extra bits and bobs like big pumps, those complicated looking heat exchangers, plus all sorts of filtration gear that takes up serious floor space. Maintenance on these babies isn't exactly quick either. Technicians spend hours checking water chemistry levels, swapping out clogged filters every few months, and dosing chemicals into the system to stop scale buildup and algae problems. The newer models have gotten pretty smart though. Many now feature fancy digital control panels that track performance metrics in real time and send alerts when something starts acting funny before it becomes a major problem down the road.

Best Applications: Where Water-Cooled Chillers Justify Their Cost

Water cooled chillers work best for setups needing lots of power (anything above 150 watts) and when multiple lasers are running at once, especially in factories that operate around the clock. These chillers become really important in hot regions where regular air cooling just doesn't cut it anymore, plus they're pretty much required in industries where tiny details matter a lot, think aerospace components or medical devices. Sure, they cost more upfront compared to cheaper alternatives, but most manufacturers find that better product quality, fewer rejects on the production line, and machines lasting much longer than expected makes all that extra spending worthwhile in the long run, especially when working under tough conditions day after day.

Head-to-Head Comparison: Key Metrics for Choosing the Right CO2 Laser Chiller

Cooling Capacity and Efficiency Under Varying Loads

The cooling capacity of a chiller, which is measured either in kilowatts or tons, basically determines how well it can handle heat management. Most often, these units need to be sized about 1.2 to 1.5 times larger than the actual power rating of the laser they're cooling. For smaller operations, air cooled chillers work just fine when dealing with low to medium power needs around 4 kW maximum, especially if the surrounding temperature stays under 35 degrees Celsius. When things get serious though, water cooled systems really shine. They handle heavy loads and changing conditions much better while keeping temperatures within very narrow ranges, usually between plus or minus 0.3 to 1 degree Celsius. According to what most manufacturers recommend, anything over 6 kW requires a chiller with at least 6,000 to 8,000 watts capacity. And guess what? The big boys in the industry almost always go with water cooled options for their long term reliability and performance in demanding environments.

Initial Investment and Long-Term Maintenance Costs

The initial price tag on air cooled chillers is typically around 30 to 50 percent lower than other options because their design is simpler and there's no need for complex plumbing work. But here's the catch they tend to guzzle more power when temperatures rise outside, which can really eat into savings down the road. On the flip side, water cooled systems come with higher purchase costs but save money in the long run. These systems are generally 20 to maybe even 30 percent more efficient with energy consumption inside temperature controlled facilities like manufacturing plants or data centers. When it comes to maintenance tasks, air cooled models demand constant attention to clean filters and coils regularly. Water cooled versions present different challenges requiring ongoing water quality management, routine pump checks, and sometimes dealing with cooling towers that might need repairs or seasonal maintenance depending on local conditions.

Space Requirements, Noise Output, and Environmental Suitability

Air cooled chillers come in compact packages that take up less space overall, but they do need good airflow around them to function properly. These units can be pretty loud too, making between 65 to 75 decibels of noise, so sometimes businesses have to install sound barriers if they're placed near offices or other quiet areas. Water cooled systems tend to run much quieter at around 55 to 65 decibels and aren't as bothered by changes in outside temperatures. The downside? They usually require additional room for things like cooling towers outside the building. When choosing between these options, environmental conditions play a big role. How much water is available locally, what the humidity levels typically are, and whether there are strict rules about discharging waste water all factor into the decision. Companies located in dry areas or places with tight regulations might find air cooled chillers more practical. Meanwhile, facilities situated near rivers, lakes, or municipal water supplies generally get better results from water cooled models because their performance stays consistent regardless of weather fluctuations.

Making the Right Choice: Matching Your Application Needs to the Optimal CO2 Laser Chiller

Small to Medium Workshops: Why Air-Cooled May Be Ideal

Small to medium sized workshops can benefit greatly from air cooled CO2 laser chillers as these offer both efficiency and affordability. These units typically handle cooling needs below 5 kilowatts and maintain stable temperatures within about plus or minus 2 degrees Celsius which works just fine for most engraving jobs and basic cutting operations. Another big plus is their small footprint that doesn't take up much workshop space. Plus installing one usually takes less time and money too maybe around thirty to forty percent cheaper than going with water cooled systems. They work pretty well even when shop temps get up to 35 degrees Celsius so no need for fancy climate control equipment. Maintenance requirements are minimal really just occasional filter cleanings and checking those fans now and then makes sense especially for businesses that don't have dedicated tech staff on hand.

Heavy-Duty and Continuous Industrial Operations: The Case for Water-Cooled

For industries needing constant, precise operation, water cooled CO2 laser chillers tend to be the go to option. These units can keep temperatures stable within about half a degree Celsius, which means the laser beam stays consistent over time and there's less drifting caused by heat buildup during long production runs something absolutely necessary for making parts with tight tolerances. Sure, they come with a price tag that's roughly 20 to 30 percent higher upfront and require special plumbing setup, but manufacturers often find that these chillers save money in the long run since they're 25 to 40 percent more efficient with energy consumption in properly controlled settings. The closed loop cooling system makes them less affected by changes in room temperature too, so they work reliably even during overnight shifts or when cutting shiny metals that naturally produce extra heat during processing.

Environmental and Operational Factors That Influence Chiller Selection

When deciding between air cooled versus water cooled chillers, there are several important factors to consider beyond just the initial costs. Ambient temperature plays a big role since air cooled systems tend to struggle when temps rise above 35 degrees Celsius, while water cooled options maintain their performance levels regardless of weather conditions. Water availability is another concern for many facilities, especially those dealing with hard water issues or facing water shortages. These places usually steer clear of water cooled systems because they come with extra expenses related to water treatment processes. Space requirements differ too. Air cooled models need plenty of ventilation space around them, whereas water cooled units typically take up less floor space but require proper plumbing connections. For facilities running non stop throughout the day, water cooled chillers generally offer better long term efficiency despite needing more complex installation work. Shorter operation periods make air cooled versions more attractive due to their simpler setup. Other things worth thinking about include local humidity levels which impact how well air cooled systems perform, noise regulations that might limit where certain equipment can be installed, and rules regarding wastewater disposal from water cooled systems. Many industrial plants find that investing in water cooled chillers pays off over time thanks to their consistent operation and precise temperature control capabilities needed for critical manufacturing processes.

FAQ Section

What is the main purpose of a CO2 laser chiller?

A CO2 laser chiller is primarily used to manage the heat generated by CO2 laser systems. This efficient cooling extends the equipment's lifespan, enhances laser performance, and ensures safety by preventing overheating.

What's the difference between air-cooled and water-cooled CO2 laser chillers?

Air-cooled chillers dissipate heat through air using fans, making them easier to install and suitable for smaller operations. In contrast, water-cooled chillers use water circuits for superior thermal regulation, which is ideal for larger systems and continuous industrial applications.

How do outside temperatures affect CO2 laser chiller performance?

Air-cooled chillers can struggle with efficiency when ambient temperatures rise above 35 degrees Celsius, while water-cooled chillers maintain stable performance regardless of external conditions due to their superior thermal management capabilities.

Why might a facility choose water-cooled over air-cooled chillers despite higher initial costs?

Facilities opt for water-cooled chillers for their precision in maintaining consistent temperatures, essential for high-demand industrial processes. They offer better long-term energy efficiency despite the higher initial cost and more complex installation requirements.

Table of Contents

- Understanding CO2 Laser Chiller Systems and Cooling Fundamentals

- Air-Cooled CO2 Laser Chillers: Design, Performance, and Ideal Use Cases

- Water-Cooled CO2 Laser Chillers: Precision, Power, and Industrial Scalability

- Head-to-Head Comparison: Key Metrics for Choosing the Right CO2 Laser Chiller

- Making the Right Choice: Matching Your Application Needs to the Optimal CO2 Laser Chiller

- FAQ Section