Understanding Thermal Load and Ultrafast Laser Chiller Capacity Requirements

The role of thermal management in ultrafast laser performance

Good thermal management makes all the difference when it comes to keeping ultrafast laser systems accurate and dependable. When these lasers run, they produce a lot of heat. If we don't get rid of that heat properly, problems start happening - things like thermal lensing effects, shifts in wavelength, and components wearing out faster than expected. That's why getting the right size chiller for an ultrafast laser matters so much. The chiller needs to handle heat removal consistently to keep the laser beam quality intact and maintain overall system stability. Research indicates that poor cooling actually cuts down on laser efficiency by around 30% for those high repetition rate operations. So thermal control isn't just nice to have, it's pretty much required if anyone wants their laser systems performing at their best.

How Ultrafast Laser Chiller Capacity impacts beam stability and pulse duration

The capacity of chillers plays a big role in keeping beams stable and maintaining proper pulse duration. Even minor temperature shifts around ±1°C can actually change the pulse length by about 5% in those fancy femtosecond systems, which causes problems like beam spreading and unpredictable outputs. For labs working on things like micro machining components or doing detailed medical imaging work, these variations really matter. When chillers are properly matched to system requirements, they help maintain that delicate balance of temperatures needed for consistent pulse energy levels and timing profiles. This kind of stability is what makes experiments reproducible in high precision settings where even tiny inconsistencies can ruin entire batches of work.

Heat load calculation: Average vs. peak power dissipation in femtosecond lasers

Getting the heat load calculations right matters a lot when picking out an ultrafast laser chiller. The engineers need to know the difference between what we call average power versus those brief bursts of energy that happen with femtosecond lasers. These little machines can throw off some serious heat spikes during their high energy pulses. On one hand, average power tells us about the basic cooling requirements. But then there are these peak loads that sometimes hit three to five times higher than normal. That's what really tests how well a chiller can handle unexpected temperature jumps. Most folks in the industry suggest adding somewhere around 20 to maybe even 30 percent extra capacity beyond what our calculations show for peak load. This gives systems some breathing room when things get unpredictable in real world operations.

Environmental factors influencing chiller capacity needs

The performance of chillers gets impacted quite a bit by factors like ambient temperature, humidity levels, altitude changes, and all sorts of airborne particles floating around. Take for example when the surrounding temperature goes up by about 10 degrees Celsius, this often leads to roughly a 15% drop in cooling power for those air cooled systems. And let's not forget about dust buildup on those heat exchanger surfaces either, which just makes things worse over time. When picking out chillers, taking all these elements into consideration helps make sure they work reliably no matter where they end up being installed. We're talking everything from super controlled lab environments right down to factories where there isn't much oversight regarding environmental conditions.

Matching Cooling Power to Laser Specifications with Precision

Thermal management begins with evaluating wattage-to-heat ratios in high-repetition-rate ultrafast systems, where waste heat scales with both average power and pulse frequency. A common guideline recommends selecting a chiller with 1.2–1.5 times the laser's rated power to accommodate thermal transients and maintain stability under maximum load.

Undersized chillers in industrial micromachining setups risk severe performance degradation. Inadequate cooling can cause temperature swings exceeding ±1°C, triggering thermal lensing and increasing pulse duration variability by up to 15%. Such instability undermines processing precision, especially in micron-level manufacturing where minor drift can ruin entire production runs.

Balancing safety margins prevents over-specification while ensuring robust performance. Excessive chiller capacity raises operational costs and reduces energy efficiency. Modern systems with variable-speed compressors and predictive load adjustment optimize cooling delivery, maintaining precise temperature control without unnecessary energy use.

Achieving Temperature Stability for Optimal Laser Performance

Importance of ±0.1°C Stability for Minimizing Thermal Lensing Effects

Keeping temperatures stable within plus or minus 0.1 degrees Celsius really matters if we want to avoid thermal lensing problems in those ultrafast laser systems. What happens here is pretty straightforward: when there are temperature differences across the system, they change how light bends through the optical parts. This causes all sorts of issues with the laser beam shape and makes everything work worse than it should. Even small changes around 0.5 degrees can mess up the beam quality and create power fluctuations that nobody wants. For people working with femtosecond lasers on tiny materials or doing serious scientific experiments where measurements need to be spot on at microscopic levels, getting this right becomes absolutely essential. Getting the right size chiller for these lasers isn't just about numbers on paper either. A properly matched cooling system keeps things running smoothly over long periods without letting performance drop off, which saves both time and money in the lab or production environment.

Integration of Ultrafast Laser Chiller Capacity with Closed-Loop Temperature Feedback Systems

Today's chillers manage temperatures really well thanks to their closed loop feedback systems which keep checking and tweaking cooling settings all the time. These systems rely on those fancy thermistors or RTD sensors to gather live data about what's happening inside the machine. With this information, they can change how fast the compressor runs, control water flow through pumps, and even adjust how heat gets transferred around. Some top end models go one step further by using smart algorithms that actually predict when things might get too hot or cold based on how lasers are being used throughout the day. This kind of foresight lets the system make adjustments before problems start showing up. The whole setup works great against unexpected changes in environment, varying workloads, and just plain old wear and tear over time. As a result, chillers match their cooling power exactly to what needs to happen right now, which means better performance overall, saves energy, and keeps equipment running longer without breakdowns.

Selecting the Right Chiller Type for Your Application Environment

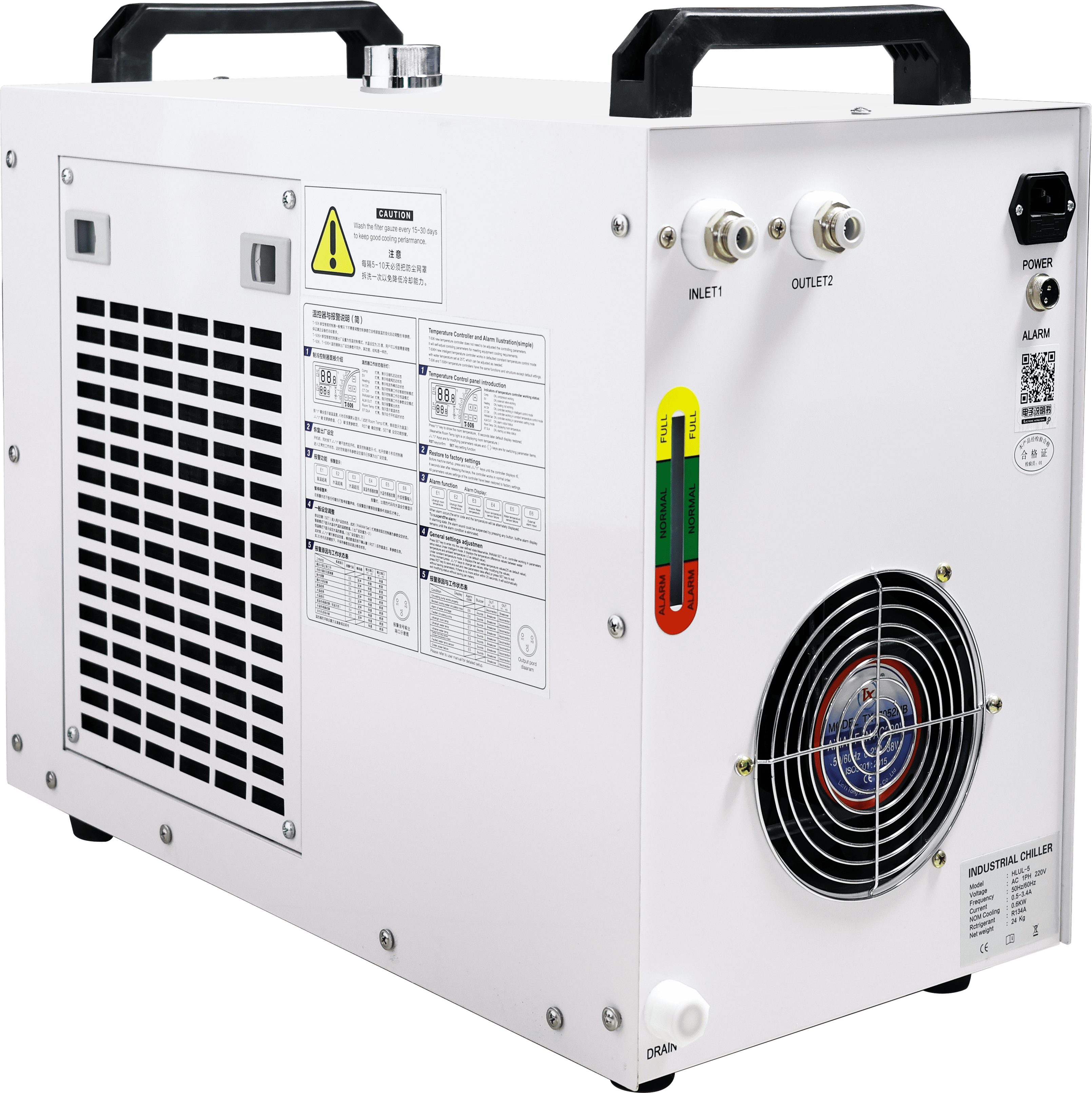

Air-cooled vs. water-cooled chillers: Efficiency trade-offs in lab environments

When deciding between air cooled versus water cooled chillers, facility managers need to weigh several factors including how efficient each system is, what kind of infrastructure exists already, and how much room there actually is available. Air cooled models are generally easier to install since they don't need complex plumbing setups, plus they tend to be cheaper upfront costs wise. However these units do need good airflow around them which can sometimes become problematic in confined spaces, plus running them might push up the temperature inside laboratories or other sensitive areas. On the flip side, water cooled chillers provide better temperature control especially when dealing with intense heat loads, making them ideal for industrial settings where precision matters most. The catch? They rely heavily on outside water supply lines and require those big cooling towers that take up serious real estate. A recent report from thermal management experts back in 2023 showed that water cooled systems typically run about 30 to 40 percent more efficiently than their air cooled counterparts under laboratory conditions, although this comes at the expense of needing roughly half again as much extra floor space for all the supporting equipment.

Recirculating chillers and compatibility with compact ultrafast laser platforms

Recirculating chillers are ideal for space-constrained setups, integrating coolant storage and pumping into compact units. Their design supports modular configurations and seamless pairing with benchtop femtosecond lasers. Despite their size, modern recirculating chillers maintain ±0.1°C stability at full ultrafast laser chiller capacity, ensuring consistent performance without thermal drift.

Smart chiller trends: Predictive load adjustment in modern photonics labs

The latest generation of chillers comes equipped with AI that predicts how much cooling will be needed next, based on live laser readings and what's happening around them in the environment. These systems look at how much electricity they're using over time and then adjust things like compressor speed and coolant flow before problems happen, which saves a lot of wasted energy. According to some tests run in 2024 at photonics labs, these smart chillers actually managed to slash energy consumption by about 25 percent and made parts last longer too. Plus, they work well when multiple lasers are running simultaneously and send out warnings when maintenance is needed somewhere. For anyone running a photonics facility that wants to stay ahead of the curve, these kinds of chillers seem pretty essential going forward.

Future-Proofing Your Investment with Scalable Chiller Capacity

Planning for Power Upgrades and Multi-Laser Integration

When selecting a cooling solution, consider future expansion. Research labs often add secondary lasers or upgrade to higher-power models, potentially increasing thermal load by 30–50%. Scalable chiller systems allow incremental upgrades without replacing core infrastructure, avoiding costly retrofits and minimizing downtime during expansions.

Modular Chiller Designs Supporting Evolving Research Demands

Modular chiller designs offer flexibility for dynamic research environments. Add-on modules enable capacity increases without full system replacement. Labs using modular systems report 40% lower upgrade costs compared to those with fixed-capacity units. Their plug-and-play integration reduces installation time from weeks to days, supporting uninterrupted experimentation.

Lifecycle Cost Analysis of Ultrafast Laser Chiller Capacity in Academic vs. Industrial Settings

When it comes to money matters, academic researchers and factory managers tend to think differently. Most university labs go for cheaper equipment at first even if it means paying more over time for maintenance and operation. On the flip side, manufacturing plants usually look at the big picture when spending cash. They'll often shell out around 25% extra upfront for chillers that save money in the long run because these systems last longer and need less fixing. The payback period? Usually somewhere between three to five years depending on how much they actually use the equipment daily. For colleges, this approach frees up funds that can then get spent on microscopes or lab benches instead. Meanwhile, factories see real gains too - their machines break down less often and workers spend fewer hours troubleshooting problems during production runs.

FAQ - Understanding Ultrafast Laser Chiller Capacity

Why is thermal management crucial for ultrafast lasers?

Thermal management is essential as it prevents issues like thermal lensing, wavelength shifts, and accelerated component wear, ensuring the laser's accuracy and dependability.

How does a chiller's capacity affect beam stability?

Chiller capacity maintains stable beam and proper pulse duration. Even a minor temperature shift can significantly affect pulse length, leading to beam instability.

What is the difference between average and peak power in lasers?

Average power reflects basic cooling needs, while peak power considers brief high-energy bursts that can greatly test a chiller's capacity to handle sudden temperature jumps.

What factors impact chiller performance?

Ambient temperature, humidity, altitude, and airborne particles can significantly affect a chiller's performance.

What are the benefits of closed-loop temperature feedback systems in chillers?

These systems provide real-time temperature management by continuously adjusting settings, improving performance, energy savings, and reducing wear over time.

Table of Contents

- Understanding Thermal Load and Ultrafast Laser Chiller Capacity Requirements

- Matching Cooling Power to Laser Specifications with Precision

- Achieving Temperature Stability for Optimal Laser Performance

- Selecting the Right Chiller Type for Your Application Environment

- Future-Proofing Your Investment with Scalable Chiller Capacity

- FAQ - Understanding Ultrafast Laser Chiller Capacity