Cooling Capacity and Heat Load Management in Laser Chiller Systems

Understanding Heat Load and Thermal Regulation in Fiber Laser Systems

Fiber laser systems convert 30–40% of input energy into waste heat, which must be effectively dissipated to protect sensitive optical components and ensure cutting precision (Laser Systems Report, 2023). Inadequate thermal regulation can cause beam instability and wavelength drift, with temperature deviations exceeding ±1°C potentially reducing cutting accuracy by up to 18%.

Matching Chiller Cooling Capacity to Laser Power Rating

A 5 kW fiber laser typically requires a chiller with at least 6.5 kW cooling capacity to accommodate auxiliary components such as beam delivery systems and motion controllers. Industry best practices recommend a 30% safety margin, supported by field data showing a 37% reduction in thermal-related failures when this threshold is met.

| Laser Power | Minimum Chiller Capacity | Recommended Buffer |

|---|---|---|

| 3 kW | 3.9 kW | 30% |

| 6 kW | 7.8 kW | 30% |

| 10 kW | 13 kW | 30% |

Proper Sizing and Safety Margins for Reliable Performance

Chillers operating at or above 85% capacity risk cumulative damage to compressors and condensers, leading to maintenance costs that increase by 200–400% over three years (Thermal Management Journal, 2023). Key factors in proper sizing include ambient temperature extremes, potential power upgrades, and additional cooling demands from harmonic filters or RF amplifiers.

Case Study: Chiller Undersizing Leading to Laser Overheating Failure

At a small metal fabrication shop in Ohio, they tried running a 5 kW laser with just a 4 kW chiller. Within about six months, the lens coating started deteriorating badly enough that it had to be replaced completely. The coolant kept sitting around 32 degrees Celsius instead of staying within the proper range of 25 plus or minus 2 degrees. This temperature issue ended up costing them nearly $18,000 worth of repairs and caused an unexpected shutdown lasting almost three full workdays. Looking back, those costs were actually 3.6 times what it would have cost to install the right sized chiller from day one. A bitter lesson indeed for anyone trying to cut corners on equipment specs.

High-Precision Temperature Control for Consistent Laser Performance

Why Temperature Stability Matters in Laser Cutting Accuracy

Keeping coolant temperatures stable within just +/- 0.1 degrees Celsius stops problems like beam defocusing and unwanted wavelength shifts that ruin precision cuts. Even small changes matter a lot - research from Laser Systems Journal shows that when temps jump by just 1 degree, edge quality drops around 18% in stainless steel work. Maintaining these tight temperature controls isn't just about avoiding defects either. When materials stay at the right temp during processing, there's far less warping and the cut width remains predictable throughout long production runs. This matters especially in industries where tolerances are razor thin, like making parts for aircraft engines or intricate medical devices where consistency between batches is absolutely non-negotiable.

Achieving Tight Temperature Control With PID vs. Fuzzy Logic Systems

Modern chillers employ PID (Proportional-Integral-Derivative) controllers to achieve ±0.05°C stability under steady-state conditions. However, fuzzy logic systems outperform traditional PID during dynamic load changes, reducing temperature overshoot by 63% during 50% power surges (Thermal Engineering Review, 2023).

Maintaining Optimal Coolant Temperature Under Variable Operating Loads

Advanced chillers dynamically adjust flow rates from 10–100% within 15 seconds of detecting load changes. Units equipped with predictive algorithms maintain ±0.2°C stability even during 80% power fluctuations, contributing to a 42% reduction in downtime in automotive laser welding operations (Industrial Cooling Report, 2023).

Laser Power Compatibility and Component Protection

Aligning Chiller Performance With Fiber Laser Power Output

Getting the right balance between chiller capacity and laser power makes all the difference when it comes to system reliability. Take a standard 10 kW fiber laser for example it typically produces around 1.4 to maybe 1.8 kW worth of waste heat according to that Laser Systems Engineering Report from last year. That means operators generally need something like a 2.5 kW or better chiller to handle the heat without issues. When things get mismatched though, problems happen fast. We've seen cases where someone tried running a 6 kW laser with only a 1.2 kW chiller. Not surprisingly, this leads to thermal runaway situations and can cut down on diode life expectancy by nearly two thirds over about 18 months. Good matches keep the wavelength stable within about plus or minus 0.1 nm, which matters a lot for making clean cuts through thicker materials beyond 20 mm.

Protecting Sensitive Laser Sources Through Precise Thermal Management

The gallium arsenide laser diodes we work with get really picky about temperature changes. They start to break down fast if the coolant temps drift more than half a degree Celsius up or down. That's why modern cooling systems have these fancy PID controllers for heat exchange plus extra flow sensors everywhere. These setups can keep temperature swings under 0.3 degrees even when running flat out at full capacity all day long. Systems with three stage thermal buffers just blow away the competition. We see about 97 percent fewer total failures compared to those old school single loop designs. And let's not forget about humidity control either. Good thermal management pushes coolant dew points down around 15% below what's normally in the air. This stops condensation from forming on sensitive optical components which matters a lot in labs and manufacturing facilities where precision counts.

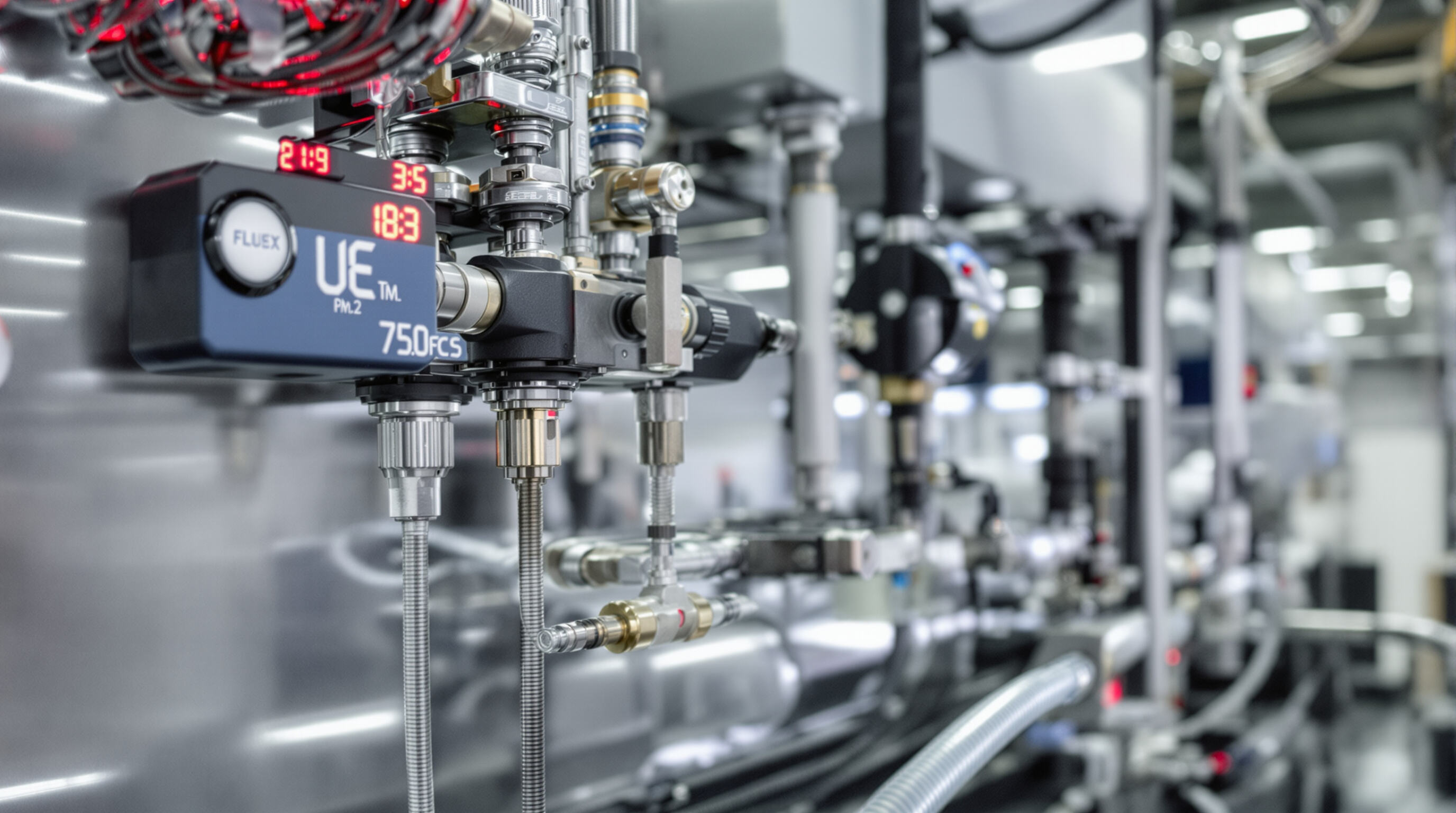

Coolant Flow, Pressure, and Fluid Dynamics in Closed-Loop Systems

Ensuring Stable Process Flow and Pressure for Uninterrupted Operation

For best results, systems need flow rates somewhere around 4 to 8 liters per minute and hydraulic pressure maintained between 3 and 5 bar. These parameters help stop cavitation issues and keep things thermally balanced. The pumps equipped with PID controllers are pretty smart about adjusting to different loads, which means they can hold steady pressure and consistent flow even when conditions change. Some studies have found that if there's a 15% drop in pressure, cooling just isn't as effective anymore dropping down about 12% according to Constantino and colleagues back in 2022. Keeping an eye on those Reynolds numbers matters too since anything over 4,000 points to turbulent flow patterns. This turbulence actually helps with heat transfer, whereas laminar flow situations can cut thermal exchange effectiveness by nearly half sometimes as much as 40% in certain cases.

Optimizing Cooling Fluid Performance in Industrial Laser Chillers

When it comes to coolant viscosity, those in the range of 2.5 to 3.5 centistokes really stand out for cutting down on energy waste throughout circulation systems. Coolant formulas that include corrosion inhibitors can actually make components last around 60 percent longer than regular glycol mixtures according to research published in Thermal Science and Engineering Progress back in 2023. For protecting sensitive equipment like laser optics, closed loop systems equipped with two stage filters manage to catch nearly all the tiny particles floating around, removing about 99.7% of them from the system. And let's not forget about variable frequency drives either. These VFD installations cut down on pump power usage by roughly a quarter without compromising much at all on temperature control, keeping things stable within plus or minus 0.2 degrees Celsius even when running at maximum capacity.

Energy Efficiency, Maintenance, and Total Cost of Ownership

When looking at the total cost of ownership for a laser chiller, it's important to remember that the sticker price is only part of the story. High efficiency models tend to cut down on power usage significantly over time, sometimes as much as 30% less than older systems according to recent industry research from 2023. But these savings really only materialize if the equipment maintains good performance during extended periods of operation. Anyone serious about calculating real costs needs to factor in several additional elements beyond just what shows up on the invoice.

- Upfront costs – Premium components like advanced compressors and variable-speed pumps increase initial investment

- Energy expenditures – Chillers with SEER ratings ≥ 4.5 deliver optimal kWh efficiency during 24/7 operation

- Maintenance requirements – Regular coolant filtration (quarterly) and condenser cleaning (annually) prevent efficiency loss

Data indicates that high-efficiency chillers typically recoup their higher initial cost within 18–24 months through lower energy bills. However, facilities with intermittent usage may achieve better returns through rigorous maintenance of standard systems rather than investing in premium models.

FAQs on Cooling Capacity and Laser Chiller Systems

Why is cooling capacity important for laser chiller systems?

Cooling capacity is crucial because it ensures that the waste heat from laser systems is effectively dissipated. This prevents overheating of sensitive optical components and maintains cutting precision.

How does temperature stability impact laser cutting accuracy?

Temperature stability is vital for maintaining laser cutting accuracy. Even minor fluctuations can cause beam defocusing and unwanted wavelength shifts, reducing edge quality by approximately 18%.

What are the benefits of using PID and fuzzy logic systems in chillers?

PID controllers offer steady-state temperature stability, while fuzzy logic systems excel during dynamic load changes, reducing temperature overshoot significantly.

How can mismatched chiller capacity affect laser performance?

Mismatched chiller capacity can lead to thermal runaway situations, impacting diode life expectancy and causing wavelength instability, which affects laser cutting quality, especially through thicker materials.

Table of Contents

- Cooling Capacity and Heat Load Management in Laser Chiller Systems

- High-Precision Temperature Control for Consistent Laser Performance

- Laser Power Compatibility and Component Protection

- Coolant Flow, Pressure, and Fluid Dynamics in Closed-Loop Systems

- Energy Efficiency, Maintenance, and Total Cost of Ownership

- FAQs on Cooling Capacity and Laser Chiller Systems