How Dual-Temperature Zone Chillers Meet the Cooling Demands of Fiber Handheld Laser Welders

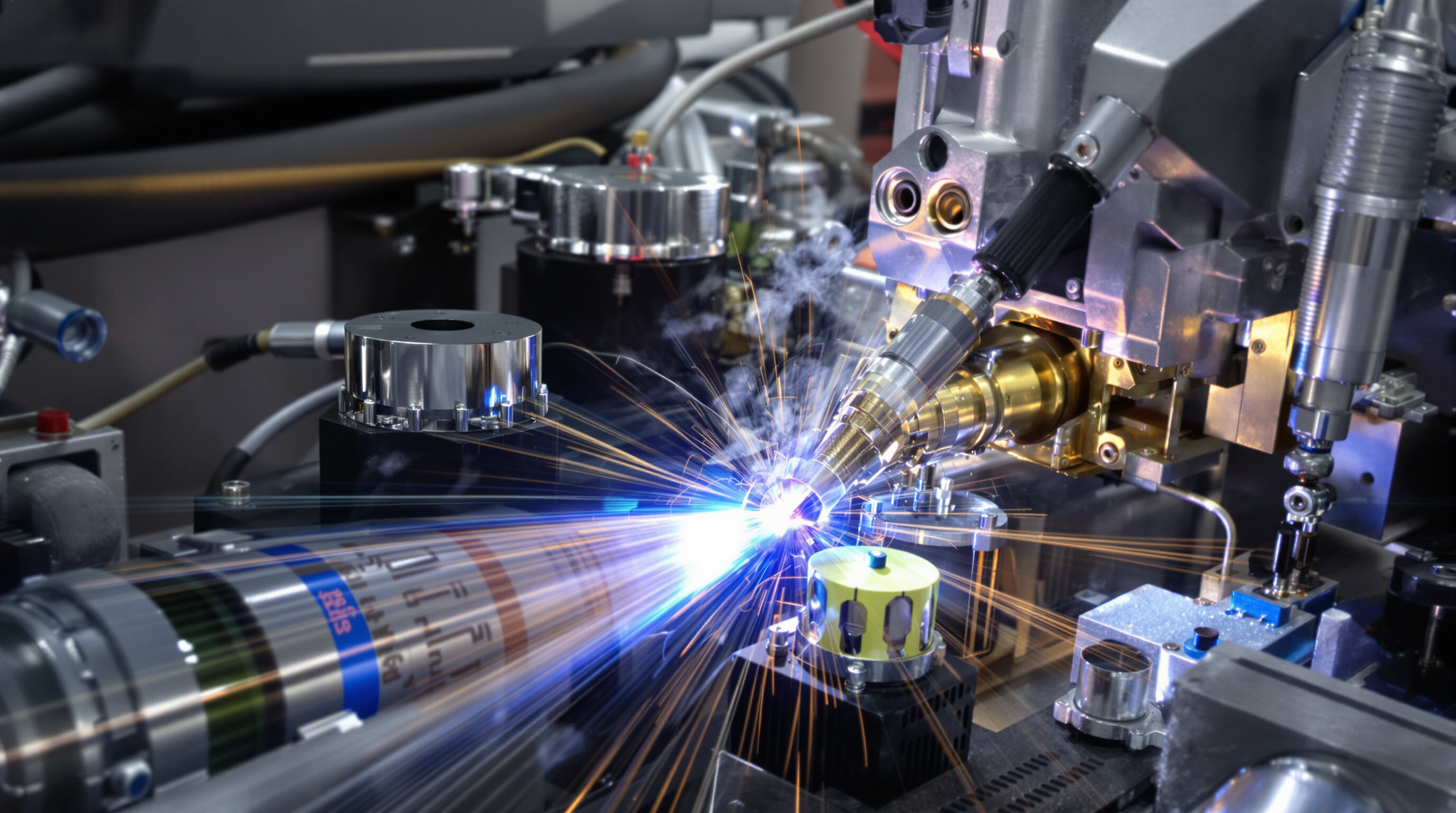

The Rise of Fiber Handheld Laser Welders and Their Thermal Challenges

The fiber handheld laser welder is becoming popular among aerospace and automotive manufacturers because it's portable and offers good precision. But there's a downside too. These compact units actually create more heat stress on important parts such as the laser diodes and those beam delivery mechanisms. Some recent research indicates that when temperatures swing more than plus or minus 2 degrees Celsius while running nonstop, the quality of the weld drops about 18 percent according to Laser Systems Journal from last year. This points clearly to why better cooling technologies are so desperately needed in this area.

Principle of Dual-Circuit Cooling: Independent Control for Laser Source and Optics

Dual temperature zone chillers work by using different refrigeration circuits for handling various thermal requirements. The main circuit keeps lasers running steady at around 22 degrees Celsius give or take half a degree, which helps keep the light output consistent. Another cooling loop brings down the temperature of optical parts to about 18 degrees plus or minus 0.3 degrees, stopping those lenses from getting warped over time. This kind of separation between cooling zones actually lets these systems release heat about 37 percent quicker compared to regular single zone chillers. Makes all the difference when doing welding jobs that run continuously without breaks.

Case Study: Performance Gains with Industry-Leading Dual-Zone Chillers

A major electromechanical manufacturer implemented dual-zone chillers in their 3kW handheld welding systems, achieving:

| Parameter | Single-Zone System | Dual-Zone System | Improvement |

|---|---|---|---|

| Thermal Recovery | 8.2 minutes | 4.7 minutes | 43% faster |

| Beam Drift | 0.12 mm/m | 0.05 mm/m | 58% reduction |

| Component Lifespan | 1,200 hours | 2,150 hours | 79% longer |

Field tests demonstrated sustained ±0.4°C temperature control during 12-hour shifts, enabling uninterrupted production of medical device components.

Precision Temperature Control for Stable Laser Output and Beam Quality

Achieving Sub-Degree Stability with Advanced Sensors and Feedback Loops

Dual temperature zone chillers these days use closed loop control systems with PT1000 platinum resistance sensors paired with PID algorithms. These systems keep temperatures stable within about 0.1 degree Celsius for fiber laser cooling circuits. The stability is actually pretty important because it helps fight against thermal lensing effects that can mess up beam collimation by as much as 18% when things get out of control (Laser Systems Journal reported this back in 2023). When the system detects any temperature changes, real time feedback kicks in and adjusts coolant flow rates pretty quickly, usually within half a second or so. This setup cuts down on thermal variations by around 89% compared to older single zone chillers which just weren't as good at maintaining consistent temperatures.

Maintaining ±0.3°C Tolerance During Extended Welding Cycles

Tests in industrial settings show that these dual zone systems maintain around plus or minus 0.3 degrees Celsius stability during eight hour straight welding sessions, which represents roughly a 60 to 65 percent boost compared to regular chillers. What makes this possible? The systems feature dual stage compressors that adjust their cooling output anywhere from 20% all the way up to full power when needed, matching whatever heat load comes along, even ones reaching 8 kilowatts. By keeping temperatures stable like this, the design actually stops those annoying temperature drift issues that plague laser diodes over time. According to research published in Industrial Laser Report back in 2022, components last about two point one extra years on average with this kind of system installed.

Balancing Fast Response and Energy Efficiency in Real-World Applications

Modern cooling systems can reach temperature changes under 1 degree per minute while cutting down on electricity usage thanks to several smart technologies. The variable speed pumps alone save about a third of energy when demand drops off, which makes sense since nobody wants to waste power when things aren't running at full tilt. Then there are these fancy algorithms that actually predict when temperatures might spike because of different welding patterns. Pretty clever stuff really. And let's not forget about those phase change materials that act as shock absorbers for sudden heat waves. These materials help boost efficiency around 20-25% compared to older fixed speed models, all while keeping temperatures stable. This matters a lot for portable laser welding equipment that runs on batteries, where every bit of saved power counts toward longer operational time between charges.

Thermal Management: Reducing Drift and Enhancing System Reliability

Impact of Heat Dissipation on Laser Beam Quality and Component Lifespan

Too much heat buildup in handheld laser welders really messes with the beam alignment and makes parts wear out faster than they should. According to an industry report from 2023, when lenses get too hot (over 45 degrees Celsius), their lifespan drops by about 19% because the coatings start breaking down. Meanwhile, those laser diodes running at near full power tend to lose roughly 12% of their maximum output strength after just 500 operating hours. The good news is there's a better way to handle this problem. Dual temperature zone chillers work wonders here by keeping the actual laser source cool enough (under 30 degrees) while also controlling the optical path temperature right around 25 degrees give or take half a degree. This helps maintain good beam quality and protects all those expensive components from premature failure.

Dual-Zone Isolation vs. Single-Zone Systems: A 68% Reduction in Thermal Drift

Separate thermal control circuits stop heat from transferring between the hot laser components and delicate optical parts. According to some tests done recently, these dual zone systems cut down on temperature fluctuations by about two thirds over traditional single zone setups as reported by Ponemon Institute back in 2023. They manage to keep things stable within half a degree Celsius even after eight hours straight of welding work. Maintaining such tight temperature control matters because it stops those annoying wavelength changes in fiber lasers. And trust me, nobody wants their laser going off track when working with tricky metals like copper or aluminum that reflect light so easily.

Design Strategies to Match Chiller Capacity with Handheld Welder Thermal Loads

Top industrial players have started implementing real time thermal load monitoring systems so they can tweak their cooling output as needed. Some of the big breakthroughs we're seeing lately? Variable speed compressors that ramp up from just 800 watts all the way to 3.5 kilowatts depending on how long those welds take. There's also these cool modular heat exchangers with removable cartridge sections that let companies expand capacity when needed. And don't forget about the smart predictive algorithms that actually forecast those sudden temperature spikes during long seam welding operations. According to field testing across various plants, these adaptable systems hit around 92 percent efficiency marks while keeping water to air heat rejection ratios under that critical 1.2 to 1 threshold, which is pretty impressive considering some facilities operate at scorching 40 degree Celsius ambient temperatures.

Key Design Features for Mobile and Industrial Durability

Compact, Vibration-Resistant Designs for Portable Laser Welding Systems

The latest dual temperature zone chillers designed for fiber optic handheld welders are getting much more compact these days. Most industrial grade units today fit within dimensions of roughly 18 inches by 12 inches by 20 inches according to Parker Hannifin's 2024 report. These smaller footprints make them easier to position where needed on factory floors. The vibration dampening mounts built into many models cut down on component wear by about 12 percent during actual field testing when compared against older designs. This matters a lot when working close to big machines that shake things up. Manufacturers like Parker have figured out ways to build these systems using CNC machined aluminum frames combined with special polymer isolators that absorb shocks. As a result, they maintain stable cooling temperatures within half a degree Celsius range even when subjected to pretty intense vibrations reaching 4G levels. Pretty impressive engineering for such small packages.

Corrosion-Resistant Materials for Harsh Manufacturing Environments

Stainless steel 316L fluid pathways now dominate 92% of new installations (ASM International 2023), resisting both chemical coolants and high-humidity workshop conditions. A recent comparative analysis of polymer composites showed polyether ether ketone (PEEK) coatings reduce galvanic corrosion by 67% in salt-spray tests, doubling maintenance intervals in marine manufacturing applications.

Integrating Handheld Laser Welding Chiller Design into Engineering Specifications

Forward-looking manufacturers now require:

| Integration Parameter | Industrial Standard | Mobile System Requirement |

|---|---|---|

| Flow Rate | 8–12 L/min @ 3 bar | 6–8 L/min @ 2.5 bar |

| Connection Ports | NPT 3/4" stainless | DIN 12mm quick-disconnect |

| Shock Resistance | IEC 60068-2-27 (25G peak) | MIL-STD-810H Method 516.6 |

This alignment ensures proper heat transfer coefficients (¥1200 W/m²K) while maintaining portable system weights under 15kg. Engineers increasingly specify unified mounting interfaces that accommodate both benchtop and vehicle-mounted deployments.

Optimizing Flow Rate, Pressure, and Water Quality for Long-Term Performance

Filtration and Conductivity Monitoring to Prevent Scaling and Corrosion

Keeping water quality under control for those dual temperature zone chillers really depends on good filtration stages and constant monitoring of conductivity levels. Most top manufacturers these days are using 5 micron particle filters along with reverse osmosis membranes. This combo cuts down dissolved solids by around 94 percent compared to just regular mesh screens according to research from Springer back in 2025. When conductivity sensors detect readings above 50 microsiemens per centimeter, they kick off automatic flushes to stop minerals from building up inside the system. The heat exchangers last much longer this way. In busy welding shops where equipment runs nonstop, components tend to stay functional about 30% longer with these advanced water treatment systems in place.

Dynamic Pump Control Using Real-Time Thermal Feedback

Today's industrial chillers come equipped with variable speed pumps that can tweak water flow between roughly 4 to 20 liters per minute depending on how hot the laser head gets. The system works smartly to stop condensation issues caused by too much cooling, all while keeping pressure fluctuations under control at around plus or minus 0.2 bar when moving along weld seams. These chillers run on sophisticated software that finds the sweet spot between quick reactions and saving power. Factory tests show these systems cycle their pumps about 62 percent less often than older fixed speed versions would during regular eight hour work periods.

Closed-Loop Deionized Circuits vs. Tap Water: Resolving the Controversy

According to field tests across various industrial settings, closed loop systems using 18 megaohm centimeter deionized water show around 40 percent less scaling problems compared to regular tap water setups. Sure, there's upfront cost for those resin beds, but once installed they cut out all those recurring expenses for water changes and pH adjustment chemicals month after month. Mobile operations benefit especially well from sealed reservoir designs that incorporate oxygen scavengers. These can keep water clean and stable for anywhere between twelve to eighteen months before needing service. That kind of reliability makes a huge difference when working on site welds in remote locations where access to fresh supplies is limited.

FAQs

What is a dual temperature zone chiller?

A dual temperature zone chiller is a cooling system that uses separate refrigeration circuits to manage different thermal requirements efficiently, ensuring precise temperature control for both laser sources and optics in fiber handheld laser welders.

Why are dual temperature zone chillers important for laser welders?

These chillers enhance welding quality by maintaining consistent temperatures, reducing heat-related beam drift, and extending component lifespan, which improves the overall reliability and precision of fiber handheld laser welders.

How do dual temperature zone chillers compare to single zone chillers?

Dual zone chillers provide better thermal recovery, reduce beam drift significantly, and extend component lifespan compared to single zone chillers, offering around 68% reduction in thermal drift and improved efficiency.

What are the key design features for dual temperature zone chillers?

Key design features include compact, vibration-resistant designs, corrosion-resistant materials, integration with handheld laser welding engineering specifications, and optimized flow rate, pressure, and water quality for long-term performance.

Table of Contents

- How Dual-Temperature Zone Chillers Meet the Cooling Demands of Fiber Handheld Laser Welders

- Precision Temperature Control for Stable Laser Output and Beam Quality

- Thermal Management: Reducing Drift and Enhancing System Reliability

- Key Design Features for Mobile and Industrial Durability

- Optimizing Flow Rate, Pressure, and Water Quality for Long-Term Performance

- FAQs