Heat Exchange Mechanisms in Laser Tube Cooling

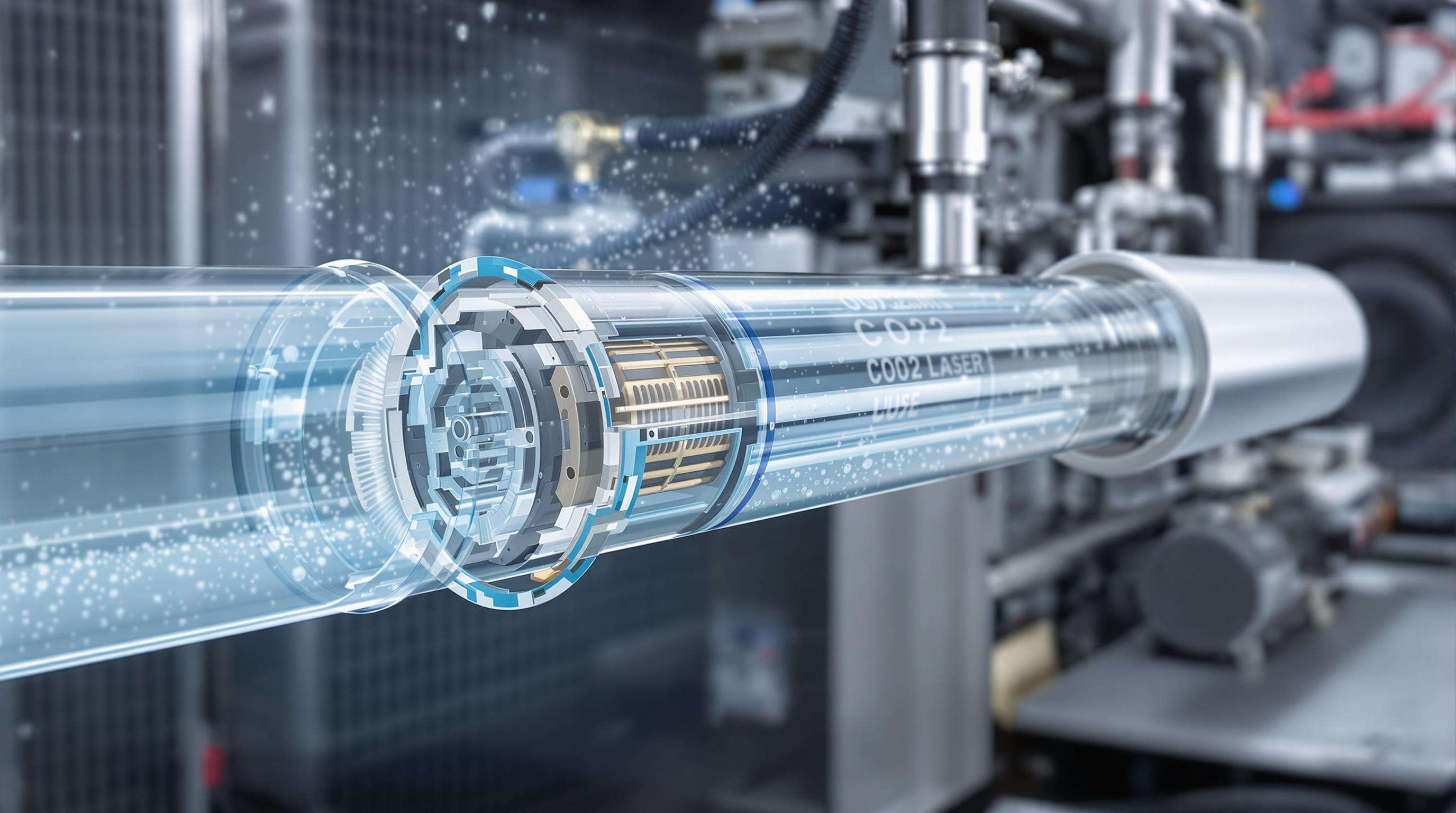

Waste heat of the CO2 lasers is evacuated by conductive and convective cooling using a water chiller. A closed loop water circuit removes the heat energy from the laser tube quartz envelope to support preferred electron mobility in the gas mixture. From there, the energy is transferred from the chiller's heat exchanger to the outside air with phase-change refrigerants that can provide 400-600 W/m²K heat transfer performance. (Re– 冷 2000) Laminar fluid flow keeps microbubbles from forming in the luminal that could disturb the laser optics.

Water Temperature's Direct Impact on Photon Generation Efficiency

Gating-process efficiency of CO, laser tube decreases 0.8%/°C more over 20°C. The density of electrons in the plasma discharge is directly influenced by the temperature of the coolant - rotational relaxation times for nitrogen molecules are about 12% shorter at 25°C than at 18°C. This mismatch has reduced the lasing efficiency, such that an increase of 3-5% in RF power is used in order to obtain equivalent beam output.

Industry Paradox: High-Precision Systems with Temperature Sensitivity

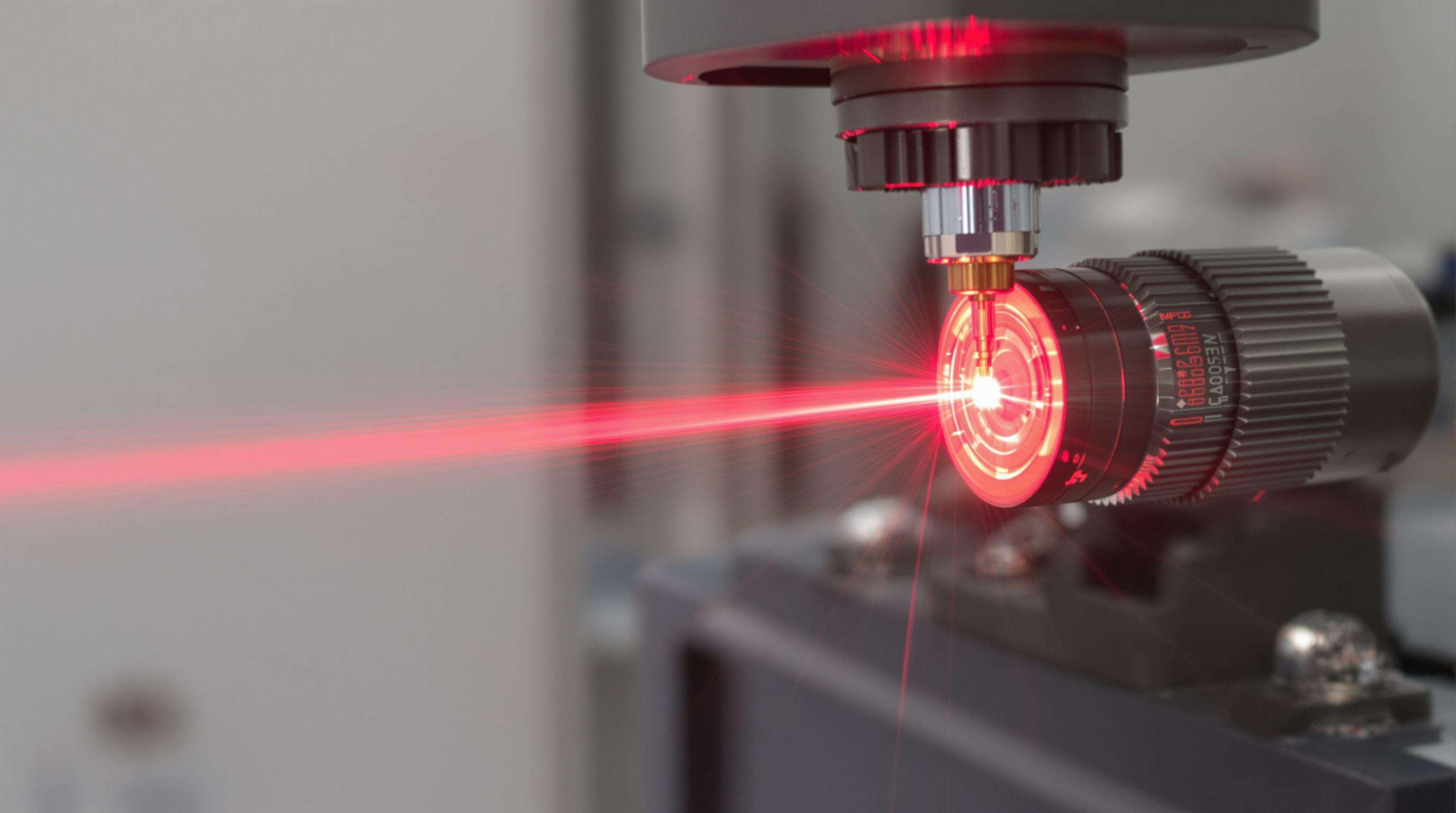

Although a lazer is an extremely-accurate cutter to within micros, a CO2 lazer can be affected by a ±1.5°C coolant variation. Thermal lensing effects in germanium output windows increase this beam divergence by 0.25 mrad per 2°C temperature rise but the nickel electrodes are subject to increasing pitting corrosion above 23°C; the sensitivity extends, in part, because 10.6 μ m photon generation requires precision in the vibrational transitions of CO 2 molecules-vibrations that are disturbed by thermal collisions with energy values greater than 220 kJ mol -1 activation threshold.

Industry-Validated 20°C-25°C Operating Window

Maintaining coolant within the 20°C to 25°C band ensures maximum photon generation efficiency and minimizes tube degradation. Operating beyond these limits accelerates electrode erosion and introduces beam instability, directly undermining engraving resolution and material penetration capabilities in CO laser systems.

Consequences of ±2°C Deviation from Ideal Conditions

A 2°C deviation from the ideal cooling threshold compromises critical processes. At 27°C, thermal lensing distorts beam collimation by up to 15%, while 18°C operation risks condensation-related electrical hazards. These deviations typically require compensatory power adjustments of 5-15%, increasing operational costs and accelerating optical component fatigue.

Case Study: 27% Power Reduction at 28°C Coolant Temperature

Documented testing revealed a 27% operational power drop when chillers permitted 28°C coolant temperatures. After 6 hours of continuous acrylic cutting, thermal distortion necessitated a 0.25mm focal length correction to maintain precision—equivalent to sacrificing 19μm engraving detail.

Thermal Lens Effect on Beam Collimation

Elevated coolant temperatures induce thermal lensing in CO2 laser optics, distorting beam collimation by 0.12-0.25 mm/m for every 3°C rise above 25°C. This refractive index shift creates focal point deviations exceeding 1.5% in high-power systems, directly correlating with wavelength drift and reduced cutting precision.

Electrode Degradation Patterns at Elevated Temperatures

RF-excited laser tubes operating above 27°C exhibit accelerated electrode wear, with nickel-plated surfaces showing 40% faster oxidation rates. Microscopic analysis identifies pitting patterns concentrated near high-current zones, reducing discharge uniformity by 15-22% over 500 operational hours.

Energy Conversion Losses in Overheated RF Excitation Systems

Overheating in RF power supplies decreases energy conversion efficiency by 0.8-1.2% per °C above 25°C, equivalent to 12-18 kW lost hourly in 15 kW laser systems. Thermal imaging shows 65% of waste heat concentrates in thyristor banks, increasing impedance mismatches that reduce peak power output by up to 27% during continuous operation.

Real-World Example: Edge Smoothness Variations During Chiller Cycling

Laser systems operating outside ±0.5°C thermal stability exhibit measurable quality degradation. A study of 40W CO lasers cutting 3mm acrylic revealed a 12% increase in edge roughness during chiller restart cycles. This occurs because thermal expansion in the laser tube alters the beam's focal length by up to 15 microns.

Material Interaction Changes with Dynamic Beam Characteristics

Variable coolant temperatures induce wavelength drift in CO lasers (9.3-10.6μm range), altering material absorption rates. For stainless steel cutting, ±1.5°C fluctuations create 0.2mm kerf width inconsistencies due to changing plasma formation thresholds.

Critical Importance of ±0.5°C Temperature Stability

Maintaining ±0.5°C temperature stability in CO2 laser chillers directly determines photon generation consistency. Advanced systems employ dual PID controllers to counteract thermal load fluctuations during continuous laser operation.

Flow Rate Requirements for Different Laser Power Classes

| Laser Power (W) | Minimum Flow Rate (L/min) | Pressure Requirements (bar) |

|---|---|---|

| 80-150 | 2-4 | 1.2-1.8 |

| 150-300 | 5-7 | 2.0-2.5 |

| 300+ | 8-12 | 3.0-4.0 |

High-power lasers (300W+) require turbocharged centrifugal pumps to maintain laminar flow at 12 L/min, preventing cavitation during rapid power cycling.

Comparison: Traditional vs. Cascade Refrigeration Systems

Cascade refrigeration systems achieve 40% greater temperature stability than single-stage units in 40°C ambient conditions. While traditional DX chillers operate at 2.8-3.5 kW/ton, cascade systems maintain 1.9-2.3 kW/ton efficiency through dual refrigerant circuits.

PID Algorithms for Real-Time Thermal Compensation

Proportional-Integral-Derivative (PID) algorithms enable precise thermal regulation by dynamically adjusting chiller outputs in response to real-time temperature feedback. Research confirms PID systems maintain water temperature within ±0.25°C even during sudden laser power surges.

Predictive Cooling Based on Cutting Parameter Analysis

Modern chillers employ machine learning to forecast thermal loads before they occur by analyzing planned cutting parameters. In field tests, this approach reduced temperature swings by 63% during intricate engraving jobs.

Multi-Zone Cooling Systems for High-Power Lasers

High-wattage laser systems (150W) implement segmented cooling circuits to address uneven thermal distribution along extended tubes. Independent temperature sensors and flow controllers target specific zones, preventing localized hotspots.

Automated Monitoring: Flow Sensors and Thermocouple Placement

Continuous monitoring of coolant flow rates and temperature gradients ensures optimal performance. Strategically positioned flow sensors in pump discharge lines provide real-time data on circulation efficiency, following industry-recognized cooling system guidelines.

Preventive Maintenance Schedule for Year-Round Stability

A preventive maintenance schedule addressing seasonal challenges includes quarterly pump inspections and biannual coolant quality analysis. Systems undergoing annual heat exchanger descaling demonstrate 40% fewer thermal shutdowns.

FAQ Section

What is the ideal temperature range for CO2 laser operation?

The ideal temperature range for CO2 laser operation is between 20°C to 25°C to ensure maximum photon generation efficiency.

What happens if the coolant temperature deviates beyond the ideal range?

If the coolant temperature deviates beyond the ideal range, it can lead to thermal lensing, increased operational costs, electrode wear, and reduced cutting precision.

How do PID algorithms help in laser cooling systems?

PID algorithms help maintain precise temperature control by dynamically adjusting chiller outputs based on real-time thermal feedback, ensuring stability within ±0.25°C.

What is the importance of maintaining a ±0.5°C temperature stability?

Maintaining ±0.5°C temperature stability is crucial for consistent photon generation, preventing beam distortion, and avoiding electrode pitting.

How does high coolant temperature affect laser efficiency?

High coolant temperatures can induce thermal lensing, accelerate electrode wear, and decrease energy conversion efficiency, leading to reduced laser performance.

Table of Contents

- Heat Exchange Mechanisms in Laser Tube Cooling

- Water Temperature's Direct Impact on Photon Generation Efficiency

- Industry Paradox: High-Precision Systems with Temperature Sensitivity

- Industry-Validated 20°C-25°C Operating Window

- Consequences of ±2°C Deviation from Ideal Conditions

- Case Study: 27% Power Reduction at 28°C Coolant Temperature

- Thermal Lens Effect on Beam Collimation

- Electrode Degradation Patterns at Elevated Temperatures

- Energy Conversion Losses in Overheated RF Excitation Systems

- Real-World Example: Edge Smoothness Variations During Chiller Cycling

- Material Interaction Changes with Dynamic Beam Characteristics

- Critical Importance of ±0.5°C Temperature Stability

- Flow Rate Requirements for Different Laser Power Classes

- Comparison: Traditional vs. Cascade Refrigeration Systems

- PID Algorithms for Real-Time Thermal Compensation

- Predictive Cooling Based on Cutting Parameter Analysis

- Multi-Zone Cooling Systems for High-Power Lasers

- Automated Monitoring: Flow Sensors and Thermocouple Placement

- Preventive Maintenance Schedule for Year-Round Stability

-

FAQ Section

- What is the ideal temperature range for CO2 laser operation?

- What happens if the coolant temperature deviates beyond the ideal range?

- How do PID algorithms help in laser cooling systems?

- What is the importance of maintaining a ±0.5°C temperature stability?

- How does high coolant temperature affect laser efficiency?