The Importance of Thermal Management in UV Laser Cooling and Ultrafast Laser Systems

Understanding UV Laser Cooling and Its Impact on System Stability

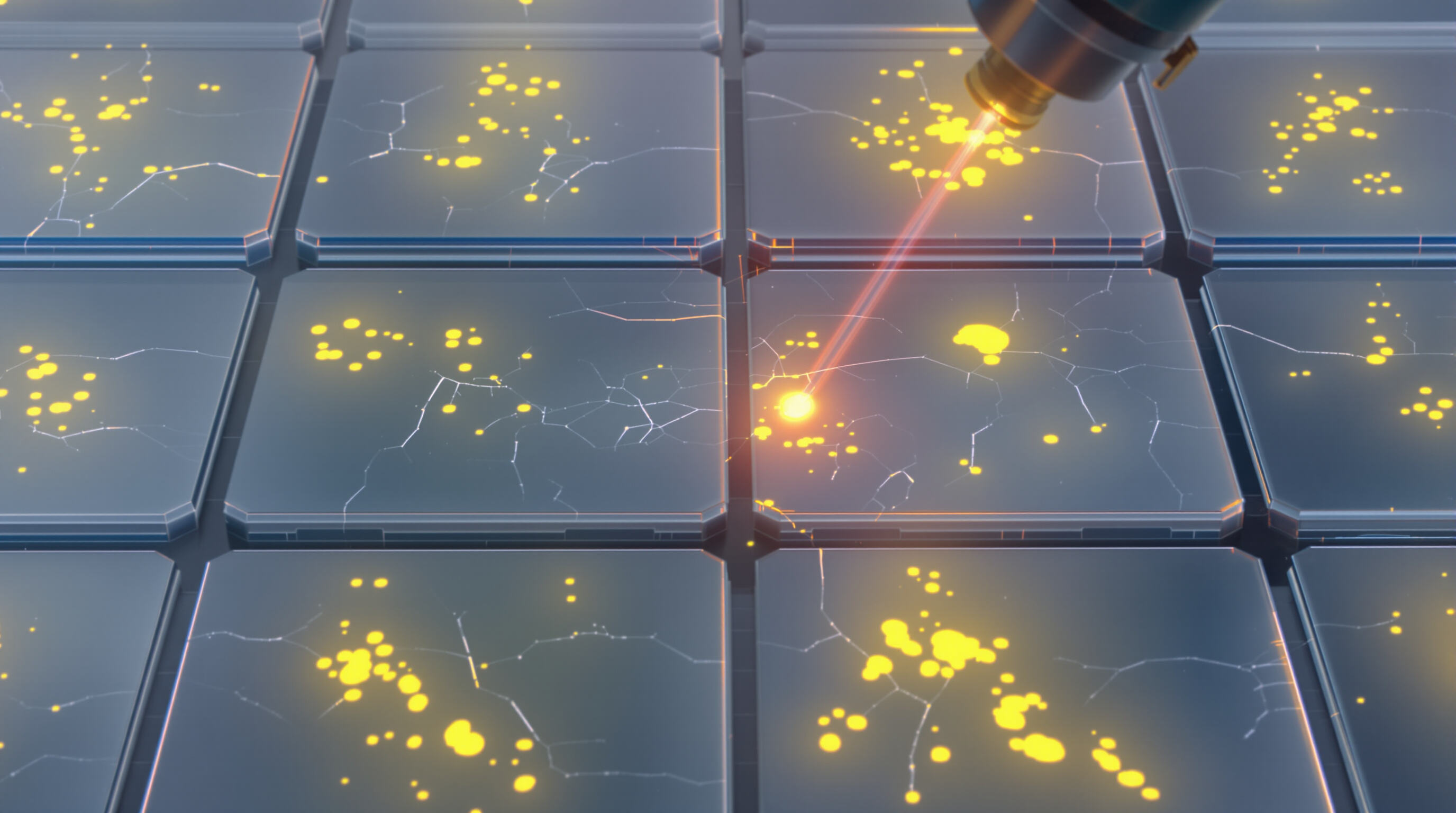

Getting UV laser cooling right makes all the difference when running those high energy operations. Small temperature changes actually mess with beam quality quite a bit sometimes, dropping it around 40% in cases where precision cutting matters most. Better cooling solutions tackle this thermal lensing problem head on. They keep the focus spot sharp and allow for really tight tolerances below 5 microns. This kind of performance isn't just nice to have but absolutely necessary for making semiconductors work properly and creating those intricate patterns on solar cells that everyone's talking about these days.

How Precise Thermal Control Prevents Efficiency Loss in Sensitive Photovoltaic Materials

Perovskite solar cells really struggle with temperature changes. Even small shifts outside the ±0.5°C range during laser processing can cause permanent damage to these materials. Fortunately, newer UV laser cooling systems have made great strides. These systems use special phase-change fluids to reach incredible stability levels below millikelvin measurements. As a result, they help keep the materials intact while pushing energy conversion rates as high as 97% in lab tests with thin film solar cells. The precision offered by this technology makes all the difference. It stops those tiny cracks from forming and avoids those nasty phase changes that happen when certain areas get too hot during manufacturing.

Growing Demand for UV Laser Cooling in High-Precision Industrial Applications

Photonics companies are reporting around 28% more UV lasers being used each year for tasks like microdrilling and cutting wafers. With this kind of growth comes a big need for new cooling approaches. Manufacturers are now looking at systems that mix microchannel heat exchangers with smart AI controls, particularly important in aerospace work where even tiny warping above 0.2 microns can ruin parts. The same goes for making quantum dots these days. Production lines need cooling responses faster than 50 milliseconds otherwise those delicate nanostructures start getting messed up when scaling up production runs.

Thermal Challenges in Laser Processing of Delicate Materials

Analyzing Heat Accumulation in Nanosecond Laser Processing of Thin-Film Solar Cells

When using nanosecond lasers for patterning thin film solar cells, we see these devices creating temperature spikes above 400 degrees Celsius at specific points. This heat causes tiny cracks in the material which can cut down on efficiency by as much as 18 percent according to research published in Nature back in 2021. Research indicates that when thermal stress goes beyond 1.2 gigapascals in those super thin photovoltaic layers, it really speeds up material degradation. This effect is especially noticeable in perovskite materials and also affects CIGS substrates quite badly. Most importantly, around two thirds of all this thermal damage happens right after the laser pulse, within just one millionth of a second. That means any good cooling system needs to handle heat dissipation quickly and efficiently since the process isn't linear at all.

Cold Ablation vs. Thermal Damage: Balancing Pulse Duration and Cooling Efficiency

Switching processes from thermal to cold ablation demands some pretty specific parameters. The pulses need to be shorter than 500 picoseconds, and the cooling system has to work fast too, at least 10 degrees Celsius per millisecond. What happens if we wait even a tiny bit? Just delaying cooling for 2 milliseconds can actually boost the recast layer thickness by about 30% in those silicon heterojunction cells. And when dealing with organic photovoltaics, getting the right balance becomes really important. Thermal budgets should stay below around 150 joules per square centimeter otherwise the polymer chains start breaking down. At the same time, manufacturers still want to remove materials cleanly and precisely without damaging what's left behind.

Case Study: Preventing Material Degradation in Solar Cell Patterning With Optimized Cooling

A 2023 industry trial achieved 0.9µm edge definition in TOPCon solar cells using a three-stage cooling approach:

- Pre-pulse chilling: Substrate stabilized at -15°C ±2°

- In-process gas assist: Plasma plume temperatures reduced by 40%

- Post-pulse quenching: Heat-affected zones limited to <5µm depth

This protocol lowered microcrack density from 12/mm² to 2.7/mm² while sustaining 98% laser throughput efficiency, demonstrating how tailored thermal management ensures less than 1% efficiency variance across production batches.

Advanced Cooling Technologies for UV and Ultrafast Lasers

Microchannel Coolers: Enhancing Heat Dissipation in High-Power Ultrafast Laser Systems

The microchannel cooler design gives around three times more surface area per volume compared to regular cooling plates. This means thermal resistance drops down to about 0.04 degrees Celsius per watt, allowing these systems to handle heat flows of up to 5 kilowatts. For those working with thin film solar materials during ultrafast ablation processes, this kind of cooling performance helps keep wavelengths stable when they really need it most. When companies start integrating these tiny structures right into their laser components, they've seen thermal stabilization times drop by roughly 40%. The faster response times make all the difference in manufacturing environments where precision matters, especially in semiconductor fabrication and other high tech production lines where even small temperature fluctuations can ruin entire batches.

Passive Cooling Solutions for Compact and Portable UV Laser Setups

New phase change materials (PCMs) that store over 250 joules per gram are making benchtop UV systems run quietly and reliably without needing regular maintenance. The paraffin based versions keep laser diodes right around their sweet spot temperature of 22 degrees Celsius, staying within half a degree for as long as eight hours even when unplugged. That kind of stability makes them perfect for looking at semiconductor failures inside those super sensitive cleanroom environments where vibrations can ruin everything. These passive cooling options cut down on electricity usage by about two thirds compared to traditional forced air methods. Plus they completely eliminate problems with beam instability caused by vibrations from fans or other moving parts in the system.

Smart Thermal Regulation: Integrating Real-Time Sensors and Feedback Controls

Today's UV laser cooling systems rely on multi spectral pyrometers that sample at around 100 Hz across twelve different monitoring points throughout the system. These systems employ machine learning algorithms to process all this information, which allows them to spot signs of thermal runaway approximately 800 milliseconds before any actual threshold gets breached. When needed, the system makes automatic adjustments to coolant flow with incredible precision down to just 0.1 degrees Celsius. What we've seen is quite remarkable actually these closed loop systems have cut down thermal lensing issues by roughly 90 percent when working on femtosecond level micromachining tasks involving photovoltaic polymers. For those dealing with high volume production environments, hybrid setups that mix traditional thermoelectric coolers with smart predictive analytics help keep energy stability between pulses within about 1.5% variance, making these systems much more reliable for day to day operations.

Evaluating Cooling Performance in High-Precision Laser Applications

Key Performance Metrics for Effective UV Laser Cooling

When it comes to UV laser cooling systems, there are several key factors that determine how well they perform. Temperature stability around plus or minus 0.1 degrees Celsius is essential, along with the system's ability to handle thermal loads measured in kilowatts per square meter, and maintaining steady flow rates throughout operations. Recent research from NIST in 2023 shows that keeping temperatures stable within this narrow range can actually make optical components last about 40% longer when running non-stop. In the world of thin film solar manufacturing, anything over 5 kW per square meter usually means we need active cooling solutions that adjust flow rates on the fly. Most engineers watch thermal resistance closely too. The formula delta T over Q gives us important insights, and anything under 0.15 degrees Celsius per watt generally points to equipment that meets industrial standards for efficiency.

Industry Benchmarks for Thermal Stability and Long-Term System Reliability

Leading manufacturers of UV lasers typically rate their cooling subsystems at around 10,000 hours between failures, which they achieve by incorporating backup pumps and parts resistant to corrosion. According to the latest report from Laser Focus World in 2024, most experts consider about 98.7% system availability as pretty much the benchmark for high precision laser cutting operations. Looking at real world data from approximately 120 different setups, there's evidence suggesting that machines capable of keeping temperature variations within just 0.2 degrees Celsius over a three thousand hour period tend to cost roughly 78 percent less in maintenance compared to standard equipment. These figures really highlight how small improvements in thermal stability can translate into significant savings down the road for industrial users.

Data Insights: Energy Thresholds and Phase Transitions in Cooled Thin-Film Processing

Real-time monitoring reveals distinct material responses during femtosecond ablation of perovskite films:

| Energy Density (J/cm²) | Material Response (Cooled vs. Uncooled) |

|---|---|

| 0.5–1.2 | Stable crystalline structure retention |

| 1.2–2.0 | Controlled amorphous phase transition |

| 2.0 | Unrecoverable lattice damage |

Research published in Advanced Materials (2022) found active cooling raises the threshold for irreversible damage by a factor of 3.2. Thermal imaging confirms cooled systems achieve 90% process repeatability, significantly outperforming the 62% repeatability of passively cooled setups.

FAQ Section

What is the role of thermal management in UV and ultrafast laser systems?

Thermal management is crucial for maintaining system stability and efficiency. It prevents temperature fluctuations that can affect the quality and precision of laser processes, especially in applications like semiconductor manufacturing and solar cell patterning.

Why is UV laser cooling important in high-precision applications?

UV laser cooling ensures the stability and accuracy needed for high-precision tasks by minimizing the effects of thermal lensing, maintaining tight focus spots, and preventing material degradation during processing.

How do microchannel coolers improve laser system performance?

Microchannel coolers increase the surface area for heat dissipation, reducing thermal resistance and allowing systems to handle high heat loads effectively, resulting in better stability and faster response times in high-tech manufacturing environments.

What advantages do passive cooling solutions offer for UV laser systems?

Passive cooling solutions, like phase change materials, offer silent and maintenance-free operation, improved energy efficiency, and significant reductions in electricity usage compared to traditional cooling methods, making them ideal for sensitive environments.