The Critical Role of Thermal Management in Ultrafast Laser System Reliability with Ultrafast Laser Chillers

How heat accumulation impacts ultrafast laser performance and component lifespan

When it comes to ultrafast laser systems, heat buildup is a real problem. Small changes in temperature can actually hurt system performance and make parts wear out faster over time. Lasers basically take electricity and turn it into light during normal operation, but this process creates quite a bit of heat along the way. If we don't manage this heat properly, all sorts of issues pop up. Wavelengths start drifting, beams get distorted because of something called thermal lensing, and overall beam quality drops significantly. Some studies suggest this affects precision applications anywhere between 30-40%. The extra heat also puts stress on important parts like laser diodes, various optical components, and the gain media inside the system. Looking at industry data, companies operating in high duty cycle environments often see component lifespans cut down by roughly half when thermal conditions aren't controlled. That's why many manufacturers now consider integrating an Ultrafast Laser Chiller not just helpful but absolutely necessary if they want their equipment to maintain consistent performance while lasting longer.

The link between precise temperature control and operational uptime

Getting temperature control just right makes all the difference for keeping systems running smoothly without unexpected stoppages. Modern cooling systems can maintain temperatures within a tight range of about 0.1 degree Celsius, which helps keep output power steady and maintains good beam quality. When there are fluctuations in temperature, they often lead to needing recalibrations or causing production hiccups. For processes that need super fine precision below 5 microns, even tiny changes in heat can make entire batches of work useless. Putting sensors at key points around the equipment allows operators to spot problems early on while there's still time to fix them before anything breaks down completely. Factories implementing these kinds of monitoring strategies have seen their downtime drop by roughly 70% because of thermal issues. What was once just background equipment for cooling now plays an active role in making sure operations stay reliable day after day.

Case study: Reducing downtime in industrial laser systems with optimized Ultrafast Laser Chiller integration

A semiconductor manufacturing plant saw real results when they swapped out their standard cooling systems for a specialized Ultrafast Laser Chiller built for machines running at high repetition rates. Before making this change, their production line was losing around 15 hours every month because components would degrade from excessive heat and thermal drift problems. Once they installed chillers equipped with those fancy microchannel heat exchangers plus some smart predictive diagnostics, monthly downtime plummeted down to only 4 hours - roughly a 70 something percent improvement. What really stood out though was how the system spotted unusual temperature trends three whole weeks ahead of time before any pumps started acting up. This gave technicians plenty of warning so they could fix things during regular maintenance windows instead of dealing with costly emergency shutdowns. The experience shows why investing in these kinds of chillers pays off big time for manufacturers concerned about keeping their equipment reliable while avoiding unexpected breakdowns.

Key Challenges in Ultrafast Laser Thermal Management and Cooling Strategies

Sources and distribution of laser-generated heat in high-duty-cycle ultrafast setups

When ultrafast lasers operate, they produce significant heat from several sources including quantum defects in the gain medium, absorption losses across various optical parts, and joule heating within the pump diodes themselves. During extended operation cycles, all these factors combine to create intense localized heating problems specifically in areas like laser crystals, mirror surfaces, and output couplers. As heat builds up quickly, it creates temperature differences throughout the system that lead to unwanted lensing effects, unstable modes of operation, and shifts in the light spectrum. These issues ultimately degrade the quality of the laser beam and reduce overall system reliability. Heat management grows even more challenging during long periods of industrial usage, so finding ways to dissipate this excess energy efficiently remains absolutely critical if manufacturers want their systems to maintain consistent performance over time.

Passive vs. active cooling: Evaluating effectiveness for sustained laser operation

For systems that don't generate too much heat, passive cooling options like heat sinks work just fine. But when dealing with those high power ultrafast lasers where heat builds up at over 100 watts per square centimeter, these passive approaches simply can't keep up. That's where active cooling comes into play. Recirculating chillers with temperature control within plus or minus 0.1 degrees Celsius provide what's needed for keeping things running without interruption. Today's laser cooling systems often include multiple stages of cooling, compressors that adjust speed based on load, and fancy heat exchangers designed to handle changing environmental conditions around them. Industrial users generally find themselves needing these complex active cooling setups for their ultrafast lasers if they want equipment that lasts and doesn't break down unexpectedly during production runs.

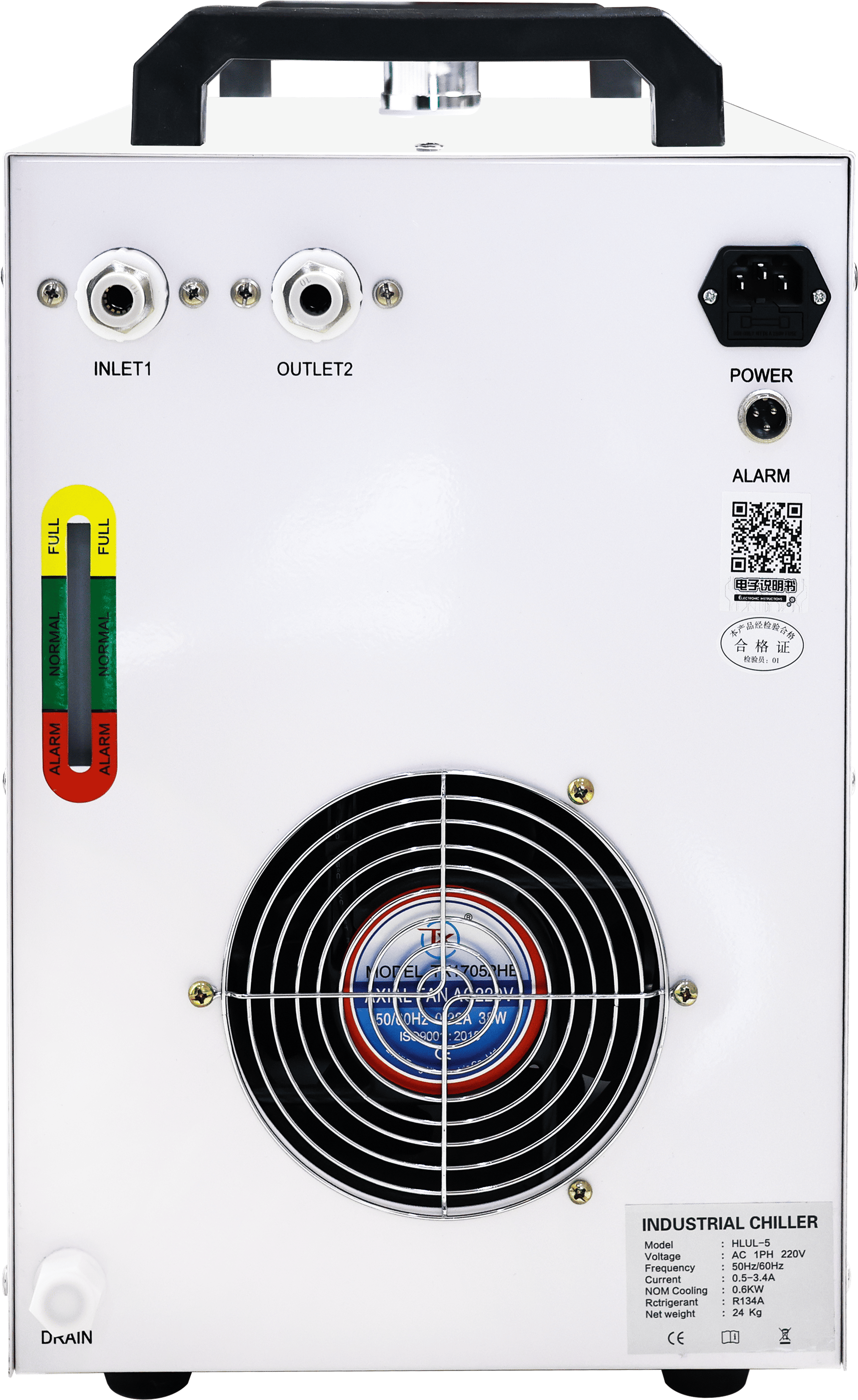

Design Features That Enhance Reliability of Ultrafast Laser Chiller Systems

Engineering for durability: Flow dynamics, material selection, and continuous operation

For chillers to work reliably over time, engineers focus on three main areas: getting the fluid flow right, picking materials that stand up to corrosion, and building parts that can handle constant operation day after day. When it comes to flow design, good systems spread heat evenly throughout the equipment while avoiding those pesky hot spots that form when flow gets turbulent around heat exchangers. The materials matter too - manufacturers now commonly use special alloys and polymer coatings that resist damage from chlorine and other chemicals found in water treatment processes. These materials help chillers last longer even in tough factory conditions where moisture and temperature extremes are common. And let's not forget about the heart of the system: industrial strength compressors and pumps. These components maintain temperature control within just 0.1 degree Celsius variations during long operating periods. That kind of stability makes a big difference because thermal drift accounts for roughly 40% of unexpected downtime problems reported in laser manufacturing facilities across the country.

Smart monitoring and predictive maintenance capabilities in modern chillers

Today's chillers come equipped with smart monitoring tech that completely changes how maintenance gets done, moving away from waiting for something to break to actually predicting problems before they happen. All sorts of sensors are scattered throughout the system, keeping tabs on things like temperature differences across components, how fast fluids are flowing, pressure fluctuations, and even checking if parts are starting to wear out. When this real time data doesn't match what the system considers normal operation, it flags potential issues such as refrigerant escaping slowly, pumps showing signs of fatigue, or when heat exchangers start getting clogged with debris. These warnings can pop up weeks ahead of actual breakdowns according to field reports from plant managers. Some of the newer systems connect right into building management software so technicians can plan repairs during scheduled downtimes rather than scrambling to fix things mid-production run when everyone is busy meeting quotas.

Validating Performance: Real-World Applications of Advanced Laser Cooling Solutions

Field data from manufacturing installations

Real world tests at various industrial manufacturing locations have shown just how important accurate thermal control really is. A major manufacturer saw their thermal issues drop by about 92 percent when they rolled out these new Ultrafast Laser Chillers throughout several plants during the past year. What's impressive is that these systems kept temperatures stable to within plus or minus 0.1 degrees Celsius, which made a big difference in how well the lasers worked and also helped components last longer before needing replacement. Looking at what happened here makes it clear that getting serious about cooling solutions can boost operations dramatically in places where heat problems used to cause constant headaches and expensive repairs all the time.

Trends in adoption: Precision machining and medical device fabrication sectors

Precision machining shops and medical device makers are increasingly turning to better cooling tech as they struggle to hit those tough quality standards. According to recent market data, Ultrafast Laser Chillers have seen about a 40% jump in usage among medical device manufacturers over the past year. Why? Because when working with lasers at the micron level, temperature matters a lot. Machining operations tell similar stories too many report around 35% boost in output after installing smart cooling systems that keep things at just the right temperature throughout long production cycles. What we're seeing here isn't just a passing fad but a real shift in how manufacturers view temperature control. Even small changes in heat can mess up those tight tolerances, so keeping thermal stability has become essential for making good products and running efficient operations across these industries.

Proactive Strategies to Maximize Uptime with Intelligent Cooling System Design

Real-time thermal feedback for proactive maintenance and failure prevention

Smart cooling systems use real time thermal sensors to keep track of laser operation conditions very accurately. The constant stream of data helps predict problems before they happen, catching small issues like dropping coolant flow rates or early signs of heat exchanger buildup long before anything breaks down. Plants that install these kinds of systems tend to prevent major breakdowns and get much longer life out of their components. A recent thermal management report from 2024 found that facilities with real time monitoring cut unexpected downtime by around 45 percent compared to places still using only regular maintenance schedules. This makes all the difference for manufacturers running expensive production lines where every minute counts.

Redundancy and fail-safe mechanisms for mission-critical laser environments

When systems absolutely must keep running, having extra cooling parts becomes really important if something goes wrong with the main setup. Things like having two pumps instead of one, multiple heat exchangers working at once, and those emergency power packs all help keep temperatures stable even when parts break down. Those special valves that automatically pop open when there's no electricity are another layer of defense against overheating problems, something most safety standards actually require nowadays. The stakes get much higher in places like hospitals making critical medical equipment. Imagine what happens if their machines stop cooling properly mid-production? Not only does it ruin expensive materials, but patients relying on those devices might end up in serious trouble because of defective products.

Aligning cooling capacity with laser duty cycles and ambient conditions: A strategic framework

Getting thermal management right means pairing chiller capacity with what the operation actually needs. Lasers that run at high duty cycles generate way more heat than others, so they demand serious cooling power. When looking at ambient conditions, facilities located in hotter areas should build in extra cooling capacity just to stay within temperature targets. Good design starts with figuring out maximum thermal output first, then factoring in how seasons affect things differently throughout the year. The right chiller selection matters too it has to work well across all those varying environmental conditions. Taking this proactive approach stops systems from overheating and keeps lasers running longer while extending the lifespan of the chillers themselves.

FAQ Section

What is the role of thermal management in ultrafast laser systems?

Thermal management is crucial in ultrafast laser systems as it helps maintain performance, prolongs component lifespan, and prevents overheating-related issues like wavelength drift and beam distortion.

How does an Ultrafast Laser Chiller improve laser reliability?

An Ultrafast Laser Chiller optimizes cooling by maintaining precise temperature control, reducing downtime, and preventing component degradation from excessive heat.

What are the benefits of real-time thermal sensors in cooling systems?

Real-time thermal sensors enable proactive maintenance by providing data that predicts problems early, helping prevent major breakdowns and extending component life.

Why is redundancy important in laser cooling systems?

Redundancies in cooling systems ensure uninterrupted operation in mission-critical environments, preventing overheating and the costly impact of system failure.

Table of Contents

- The Critical Role of Thermal Management in Ultrafast Laser System Reliability with Ultrafast Laser Chillers

- Key Challenges in Ultrafast Laser Thermal Management and Cooling Strategies

- Design Features That Enhance Reliability of Ultrafast Laser Chiller Systems

- Validating Performance: Real-World Applications of Advanced Laser Cooling Solutions

- Proactive Strategies to Maximize Uptime with Intelligent Cooling System Design

- FAQ Section