How Industrial Air Cooled Water Chiller Systems Work and Their Core Components

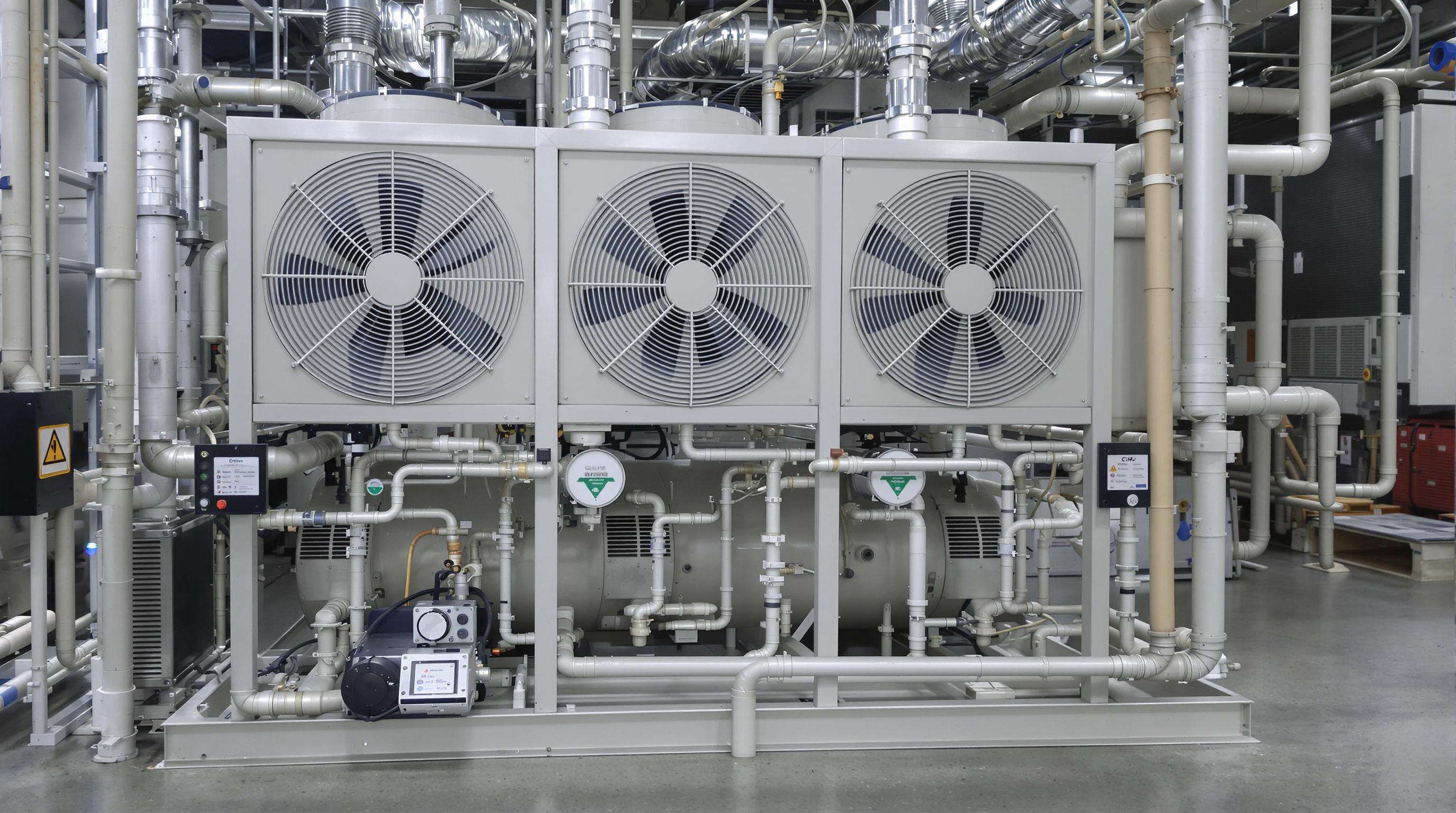

Air cooled industrial water chillers work by taking heat away from manufacturing operations through what's called a closed loop refrigeration system. The process involves running cold water through various types of machinery such as computer numerical control (CNC) machines and plastic injection molding units. As this water passes through these machines, it picks up excess heat and goes back to the evaporator part of the system. Once there, the collected heat gets pushed out through special condenser coils and powerful axial fans instead of relying on traditional cooling towers. Because they don't require large amounts of water, these chillers are particularly good choices for areas where water resources are limited or for factories looking to cut down on maintenance headaches since there's no tower to clean or maintain.

What Are Air-Cooled Chillers and How Do They Work?

Air cooled chillers work through what's called a vapor compression refrigeration cycle. Inside the system, refrigerant picks up heat from process water as it passes through the evaporator section, turning into a low pressure gas. Next comes the compressor which cranks up the pressure of this gas, making it hotter before sending it along to the condenser unit. At this stage, fans blow ambient air across the condenser coils, cooling down the refrigerant until it changes back into liquid form and pushes all that excess heat outside the building. Take a standard 50 ton model for example it can handle around 600 thousand BTUs per hour. That kind of capacity makes these units pretty effective at keeping things cool in workshops or manufacturing spaces where temperature control matters most.

Key Components of Industrial Air Cooled Water Chiller Units

The four essential components include:

- Compressor: Drives refrigerant circulation (scroll for 60 tons, screw for 100+ tons)

- Condenser: Rejects heat via aluminum fins and fans

- Expansion Valve: Regulates refrigerant flow into the evaporator

- Evaporator: Transfers heat from process water to refrigerant

Modern units integrate variable-speed drives (VSDs) and IoT-enabled control panels to optimize energy use and monitor performance.

Air-Cooled vs. Water-Cooled Chiller Systems: Key Differences and Trade-offs

When it comes to maintenance requirements, air cooled systems generally need around half as much upkeep compared to their water cooled counterparts since there's no need for cooling towers, water pumps or all those chemical treatments that go along with them. The tradeoff though is that these systems actually use about 10 to maybe even 15 percent more power when operating in really humid conditions. Water cooled chillers tend to perform better overall measured by their coefficient of performance numbers especially in places where temperatures stay pretty consistent throughout the year. But let's not forget the bottom line here water cooled systems typically cost about twenty percent more upfront to install. For businesses dealing with tight spaces, air cooled options remain popular despite everything else because they take up roughly forty percent less room on the floor. That kind of space savings can be absolutely critical in older buildings or locations where expansion isn't really an option.

Critical Applications of Industrial Air Cooled Water Chillers in Manufacturing

Industrial air cooled water chillers deliver targeted temperature control for manufacturing processes requiring ±0.5°C precision or better. Their self-contained design eliminates the need for cooling towers, making them ideal for facilities with space constraints or limited water access.

Precision Cooling in CNC Machining and Injection Molding

Air cooled chillers play a critical role in CNC machining by keeping spindle temps under 25 degrees Celsius. When cutting tools get too hot, they expand which causes all sorts of problems on the shop floor. According to a study from Precision Manufacturing Journal back in 2023, this thermal issue accounts for around 12% of errors when making automotive parts. For injection molding operations, these same chillers make a real difference too. Plastic solidifies anywhere between 18 to 22 percent quicker with active cooling versus just letting things cool down naturally. Faster cycles mean money saved, but there's another benefit nobody talks about enough warping defects drop significantly in those precision parts we manufacture for medical devices. The housings need to fit perfectly after all.

Process Cooling for Chemical, Pharmaceutical, and Food Production

Air cooled chillers play a vital role in chemical batch reactors where maintaining exothermic reactions within just 5 degrees Celsius of target temperatures is absolutely essential. When these systems fail, we're talking about massive costs across the industry - over 740 million dollars lost every year due to emergency shutdowns according to Process Safety Institute research from last year. Moving into pharmaceutical applications, chillers must meet strict ISO Class 5 standards for cleanrooms. This requires HEPA filtered airflow systems that keep contaminants at bay, something that's literally life saving when manufacturing vaccines. And let's not forget about food processing either. These chillers can bring down sauce temperatures from scalding hot 90 degrees all the way to safe storage levels of 4 degrees in less than ninety minutes. That kind of rapid cooling meets USDA requirements for controlling pathogens while eliminating the need for messy ice bath methods commonly used in traditional kitchens.

Energy Efficiency and Cost Performance of Air Cooled Water Chiller Systems

Understanding SEER and COP: Measuring Chiller Efficiency

When looking at industrial air cooled water chillers, technicians often refer to two main efficiency indicators: the Seasonal Energy Efficiency Ratio or SEER, and the Coefficient of Performance known as COP. The COP basically tells us how much cooling power we get out versus what goes in terms of electricity. Most new systems these days sit somewhere between 2.5 and 6.0 on this scale. Then there's SEER which takes into account those pesky seasonal temperature changes throughout the year. Facilities that run all seasons benefit most from knowing their SEER ratings. Take a typical chiller with a COP rating around 4.0 - that means for every kilowatt of power used, it delivers about four kilowatts worth of cooling effect. Industry data suggests such units can slash energy bills roughly 35-40% when swapped against older equipment still lingering in some plants.

Variable Speed Drives and Smart Controls for Maximum Energy Savings

Variable speed drives or VSDs are pretty smart tech that can tweak compressor and fan speeds on the fly based on actual cooling needs. This cuts down on wasted energy when systems aren't running at full capacity. The really clever part comes from smart control systems that look at things like outside temperature, how humid it is, and what specific processes need cooling at any given moment. When manufacturers put these technologies together in their HVAC systems, they typically see around 15 to 30 percent better efficiency compared to older fixed speed models. A recent study looking at industrial HVAC trends from last year backs this up, showing why so many facilities are making the switch despite the initial investment cost.

Balancing Higher Initial Costs with Long-Term Operational Gains

Air cooled chillers tend to cost around 10 to 20 percent more initially compared to their water cooled counterparts. But what they lack in initial price, they make up for over time because there's no need for complex cooling towers or expensive water treatment systems that require constant attention. For businesses located where water is scarce or expensive, this means avoiding those ongoing water bills that can really add up month after month. Looking at the bigger picture, research indicates that good quality air cooled systems actually end up costing between 20 and 35 percent less overall when considering both energy efficiency gains and fewer breakdowns across a ten year period. The math just adds up differently in the long run despite that higher starting investment.

Thermodynamic comparisons between air- and water-cooled chillers highlight scenarios where air-cooled models provide superior cost-performance ratios despite marginally lower COP ratings.

Sustainability Advancements in Industrial Air Cooled Water Chiller Design

Industrial air cooled water chiller systems are adopting groundbreaking sustainability measures to align with global climate goals. Manufacturers now prioritize two critical areas: refrigerant innovation and compliance with tightening environmental regulations.

Transition to Low-GWP Refrigerants and Phase-Out of R-22

These days, many modern cooling systems are switching to newer refrigerants such as R-513A with a Global Warming Potential (GWP) rating of around 573 and R-1234ze which has an impressively low GWP of just 7. Compared to the old R-22 refrigerant that had a massive GWP of 1,810, this represents a reduction in environmental impact anywhere from 78% all the way down to nearly 99%. The latest standards from AHRI released in 2023 actually require this shift for commercial chillers, setting a target of keeping their overall GWP below 750 by the year 2025. For businesses still running older equipment, there's good news though. Retrofitting existing units with properly matched compressors and condenser components can help them comply with these new regulations without having to completely replace entire systems right away.

Environmental Compliance: Meeting EPA and F-Gas Regulations

According to the latest market analysis for industrial chillers in 2024, around two thirds of manufacturers have started incorporating designs that meet F Gas Regulation standards. These include things like advanced leak detection sensors and those sealed scroll compressors that prevent refrigerant leaks. The European Union has recently tightened its rules, mandating a significant cut in hydrofluorocarbon emissions from industrial chillers - about half reduction needed by 2030. To comply, companies must implement practices such as capturing refrigerants when performing maintenance work. Some of the top performing units on the market today are combining environmentally friendly refrigerants with innovative heat recovery systems. These systems can actually reuse between forty to sixty percent of what would otherwise be wasted heat energy, redirecting it towards building heating needs or even warming up process water before it enters production lines.

These advancements cut annual CO₂ emissions by 12–18 metric tons per chiller unit while maintaining SEER ratings above 14.5, proving environmental responsibility need not compromise performance.

Future Innovations and Market Evolution in Air Cooled Chiller Technology

Industrial air cooled water chiller systems are evolving through smart technology integration and strategic responses to global market demands. The sector’s 5–7% projected CAGR (2024–2028) reflects increasing adoption of IoT capabilities and modular designs that align with sustainability mandates.

IoT and AI-Driven Predictive Maintenance in Process Cooling

AI algorithms now analyze compressor performance data and refrigerant flow rates to predict component failures 72 hours in advance. This reduces unscheduled downtime by 35% in industries like injection molding, where thermal stability directly impacts product quality.

Modular Chiller Designs and Industry 4.0 Integration

Manufacturers deploy scalable chiller arrays that connect directly to SCADA systems, allowing capacity adjustments within ±10% of real-time production needs. Standardized interfaces enable integration with automated material handling systems, cutting energy waste during low-demand periods.

Global Market Trends: Growth in Asia-Pacific and North America

Asia-Pacific dominates 52% of new installations, driven by electronics manufacturing expansion in China’s Yangtze River Delta. North America prioritizes EPA-compliant units with variable speed compressors, achieving 18% better SEER ratings than legacy models.

Frequently Asked Questions (FAQ)

What is the key advantage of air cooled chillers in areas with limited water resources?

Air cooled chillers do not require large amounts of water, making them advantageous for areas with limited water resources. They eliminate the need for cooling towers and water pumps, reducing maintenance requirements and costs associated with water usage.

How do air cooled chillers work in the refrigeration cycle?

Air cooled chillers operate through a vapor compression refrigeration cycle, where refrigerant absorbs heat from process water, turns into low pressure gas, is compressed, cooled down by fans in the condenser unit, and the excess heat is expelled from the building.

What are the main components of industrial air cooled chillers?

The key components include the compressor, condenser, expansion valve, and evaporator. These components circulate refrigerant, reject heat, regulate refrigerant flow, and transfer heat from process water.

How do air cooled chillers compare to water cooled systems in terms of maintenance?

Air cooled systems generally require less maintenance compared to water cooled ones, as they do not rely on cooling towers and extensive water treatment processes. However, they might use more power in humid conditions.

Which industries benefit from air cooled chillers?

Industries such as CNC machining, injection molding, chemical production, pharmaceuticals, and food processing greatly benefit from air cooled chillers due to their precision cooling capabilities and space-saving design.

Table of Contents

- How Industrial Air Cooled Water Chiller Systems Work and Their Core Components

- Critical Applications of Industrial Air Cooled Water Chillers in Manufacturing

- Energy Efficiency and Cost Performance of Air Cooled Water Chiller Systems

- Sustainability Advancements in Industrial Air Cooled Water Chiller Design

- Future Innovations and Market Evolution in Air Cooled Chiller Technology

-

Frequently Asked Questions (FAQ)

- What is the key advantage of air cooled chillers in areas with limited water resources?

- How do air cooled chillers work in the refrigeration cycle?

- What are the main components of industrial air cooled chillers?

- How do air cooled chillers compare to water cooled systems in terms of maintenance?

- Which industries benefit from air cooled chillers?